Water Softener

Features of Water Softener

- Reduces water hardness to below 1 ppm

- Custom design tailored to project requirements

- Use of high-capacity cation exchange resins

- Durable body construction from carbon steel with epoxy coating or stainless steel

- Fully automatic control with PLC and solenoid valves

- Fast and cost-effective regeneration with salt solution (NaCl)

- Engineered hydraulic design to prevent water channeling

- Technical support, reliable warranty, and professional after-sales services

Support services and specialized consultation

Customized solutions for clients

Quality and performance assurance of products

Expertise in wastewater treatment technologies

Additional Information

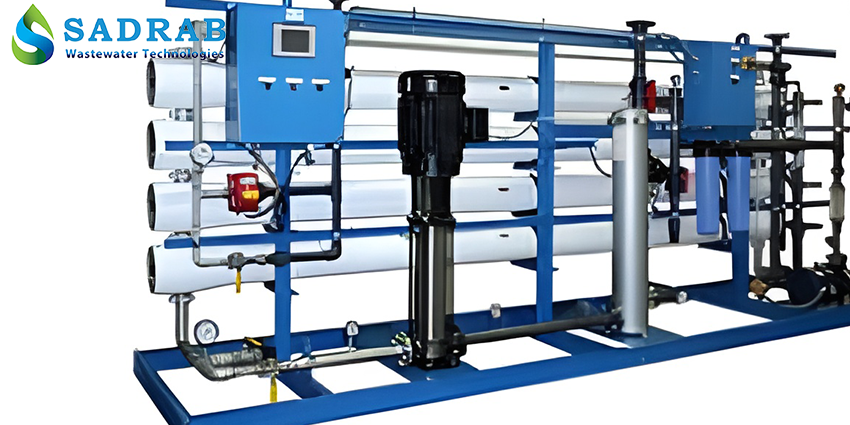

Sadrab Industrial Water Softener: A solution for removing water hardness and protecting equipment

Water hardness, caused by the presence of calcium and magnesium ions, is one of the main challenges in various industries and facilities. It can lead to scaling, reduced equipment efficiency, and increased maintenance costs. The industrial water softener is recognized as an effective solution for removing hardness ions and producing soft water. Sadrab Caspian Purification Company, with over a decade of experience in the water and wastewater treatment industry, offers high-performance industrial softeners with customized designs. These devices are suitable for industrial, commercial, and municipal applications. In this page, we will explore the features, technologies, advantages, and how to select the right Sadrab industrial water softener.

What is an industrial water softener?

An industrial water softener is a device that uses the ion exchange process or other advanced methods to remove calcium and magnesium ions (the causes of water hardness) and produce soft water. These devices are typically used in water pre-treatment systems to protect boilers, cooling towers, and reverse osmosis systems. Sadrab water softeners are designed in various capacities, ranging from a few cubic meters to hundreds of cubic meters per hour, to meet different needs.

Features of Sadrab Industrial Water Softener:

Sadrab offers industrial water softeners with the following features:

High-Quality Resins: Use of high-capacity cation exchange resins.

Diverse Capacity: Suitable for water treatment with flow rates from 5 to 500 cubic meters per hour.

Durable Design: Constructed with carbon steel body coated with epoxy or stainless steel for corrosion resistance.

Fully Automated: Equipped with automatic or manual valves for resin regeneration.

Effective Hardness Removal: Reduces water hardness to less than 1 ppm (depending on requirements).

After-Sales Service: Technical support, reliable warranty, and periodic maintenance services.

For ordering Sadrab industrial water softeners, contact us!

Technologies Used

Sadrab water softeners utilize the following technologies:

- Ion Exchange: Use of cationic resins to replace calcium and magnesium ions with sodium.

- Resin Regeneration: Washing the resin with a salt solution (NaCl) to restore its ion exchange capacity.

- Automatic Control: PLC systems to manage the regeneration and washing process.

- Advanced Hydraulic Design: Uniform distribution of water over the resin bed to prevent channeling.

- Durable Materials: Corrosion-resistant coatings and high-durability resins.

Advantages of Sadrab Industrial Water Softeners

Equipment Protection: Prevents scaling in boilers, heat exchangers, and pipelines.

Increased Efficiency: Improves the performance of industrial systems such as cooling towers and RO systems.

Economic Savings: Reduces repair and energy consumption costs caused by scale buildup.

Environmental Sustainability: Decreases the use of anti-scaling chemicals.

Flexibility: Custom design for industrial, commercial, and residential applications.

Professional Support: Expert consultation, installation, and maintenance services by the Sadrab team.

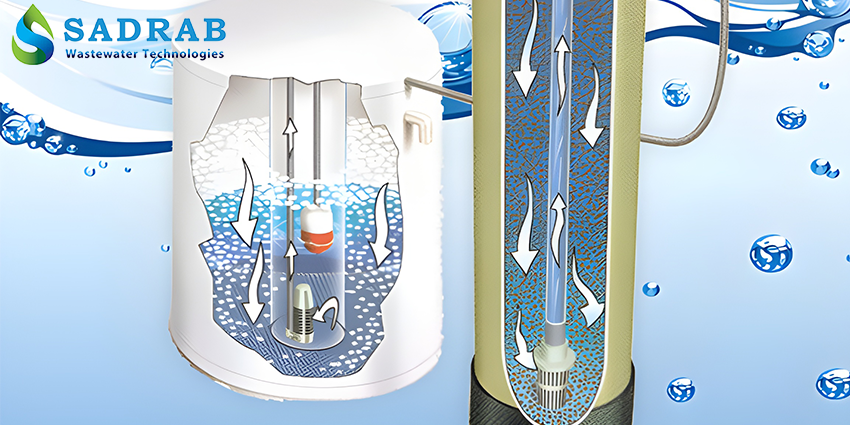

How Sadrab Industrial Water Softener Works

The Sadrab water softener operates through the following steps:

Incoming Hard Water: Water containing calcium and magnesium ions enters the softener.

Ion Exchange: Cationic resins absorb hardness ions and release sodium ions.

Outgoing Soft Water: Water with very low hardness exits the device.

Resin Regeneration: At regular intervals, the resin is washed with a salt solution to restore its capacity.

Return to Normal Operation: After regeneration, the softener is ready for use again.

This process ensures that the output water is suitable for industrial and facility applications.

Factors to Consider When Selecting an Industrial Water Softener

To choose the right water softener, consider the following factors:

| Factors | Description |

|---|---|

| Incoming Water Hardness | High hardness water requires resins with higher capacity. |

| Water Flow Rate | From 5 to 500 cubic meters per hour, depending on project requirements. |

| System Type | Manual or automatic, depending on the level of automation needed. |

| Maintenance Costs | Includes periodic resin replacement and regeneration salt supply. |

| Installation Space | Compact design for industrial environments with limited space. |

The Sadrab team analyzes the incoming water hardness and your project needs to recommend the best water softener. Contact us for a free consultation!

Price of Sadrab Industrial Water Softeners

The price of water softeners depends on the following factors:

System Capacity: Higher flow rate softeners cost more.

Body Material: Carbon steel with epoxy coating or stainless steel.

System Type: Manual or automatic (with solenoid valves and PLC).

Resin Quality: Higher capacity resins come at a higher price.

Installation Services: Professional installation and training by the Sadrab team.

For accurate pricing and special offers, contact the Sadrab sales team!

Maintenance Tips

Resin Regeneration: Every 1-7 days, depending on water hardness and treatment volume.

Resin Replacement: Every 5-7 years, depending on water quality and regeneration frequency.

Pressure Check: Periodic inspection of pressure gauges to prevent resin clogging.

Sadrab Services: Technical support, resin and salt supply, and specialized repairs.

About Sadrab Caspian Purification Company

Sadrab, relying on technical knowledge and specialized teams in environmental engineering, mechanics, and chemistry, is one of the leading water and wastewater treatment companies in Iran. We are committed to providing sustainable solutions through the successful implementation of projects across various industries.

Vision: A leader in providing water treatment technologies for industries and communities.

Values: Quality, innovation, and customer satisfaction.

Services: Consulting, design, production, installation, and support.

For collaboration with Sadrab, contact us today!

Conclusion

Industrial water softeners from Sadrab are an efficient solution for removing water hardness and protecting equipment in industrial, commercial, and municipal facilities. With advanced technology, durable design, and professional services, Sadrab ensures the quality of water and the sustainability of your processes. To select the appropriate water softener and receive free consultation, contact our team.

FAQ

Sadrab industrial water softeners are suitable for a wide range of industries, including power plants, food manufacturing factories, pharmaceuticals, petrochemicals, urban facilities, and heating and cooling systems. Wherever there is a need for soft water to prevent scaling, the use of water softeners is essential.

Resin regeneration typically occurs every 1 to 7 days, depending on the water hardness and usage volume. Complete resin replacement is usually required every 5 to 7 years, provided proper maintenance is followed.

In the manual model, the resin regeneration process must be done manually, while the automatic model has electric valves and controllers (such as PLC) that perform the regeneration process automatically. Automatic models are more suitable for high-consumption systems and do not require a permanent operator.

To select the appropriate capacity, factors such as water flow rate, incoming water hardness, system operating hours, and installation space must be considered. Sadrab’s technical team will conduct an initial analysis and recommend the most suitable model for you.