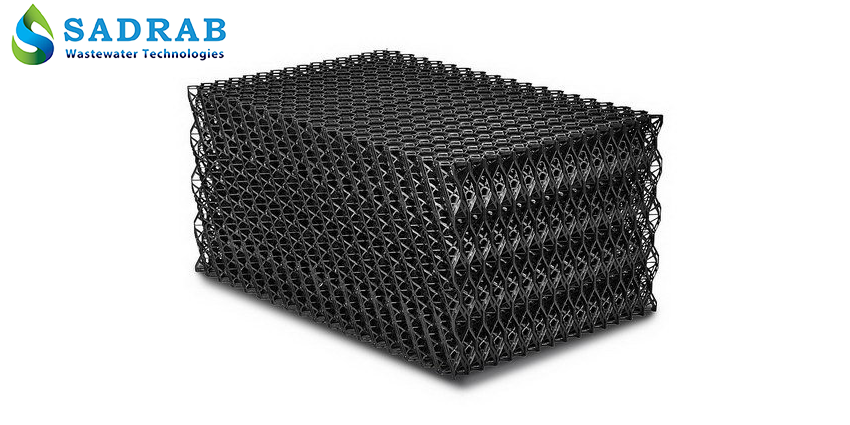

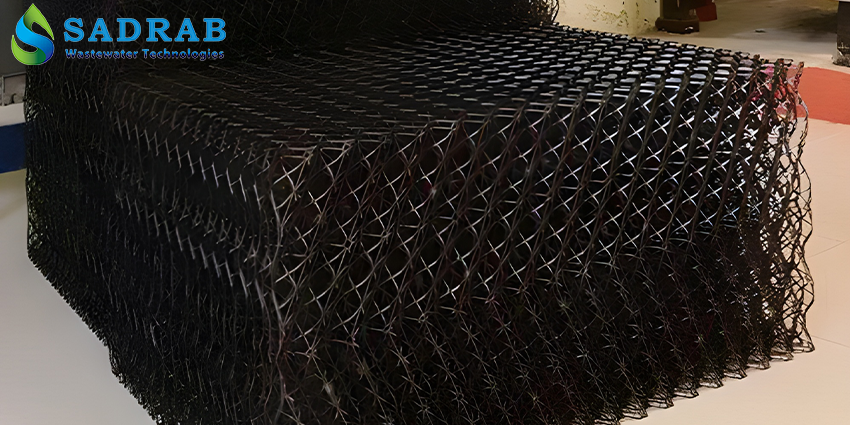

Splash Grid Packing

Features of Splash Grid Packing:

- Modular and flexible design

- High thermal exchange efficiency

- Excellent resistance to scaling and clogging

- High temperature tolerance (up to 95°C)

- Optimized water consumption

- Chemical and UV resistance

- Easy to clean and maintain

- Customizable to project requirements

Expert support and technical consulting

Customized solutions tailored to client needs

Guaranteed product quality and performance

Specialized expertise in wastewater treatment technologies

Additional Information

Sadrab Splash Grid Packing: A Smart Choice for Enhancing Cooling Tower Efficiency

Cooling towers are essential components across various industries for cooling water used in industrial processes. One of the critical elements of these towers is the packing, which plays a vital role in improving cooling efficiency. With over a decade of experience in the water treatment and industrial equipment sector, Sadrab Caspian Refining Co. introduces Splash Grid Packing as an advanced solution to optimize the performance of cooling towers.

This product, engineered with innovative design and high-quality materials, is a smart choice for petrochemical industries, power plants, and other manufacturing sectors.

What is Splash Grid Packing?

Splash Grid Packing is a type of packing used in cooling towers to increase the contact surface between warm water and cool air. This packing, with its grid-like structure, breaks the water into smaller droplets, increasing the contact area with air, which leads to better heat exchange and faster cooling of the water. Splash Grid Packing is especially suitable for dirty or high-salinity water, as its open structure prevents scaling and clogging.

How It Works

Breaking water into small droplets: Splash Grid Packing breaks water into fine droplets, increasing the contact surface with air.

Increasing contact time: The grid-like structure extends the contact time between water and air, enhancing heat exchange.

Uniform distribution: The packing distributes water evenly to prevent the formation of hot spots.

Reducing scaling: The open design of the packing prevents the accumulation of deposits and algae.

Features of Sadrab Splash Grid Packing

Sadrab has designed Splash Grid Packings with the following features:

High-quality materials: Made from polypropylene (PP) blended with a percentage of heavy polyethylene, resistant to corrosion, UV radiation, and chemicals.

Advanced grid design: Honeycomb or corrugated structure that maximizes the contact surface area.

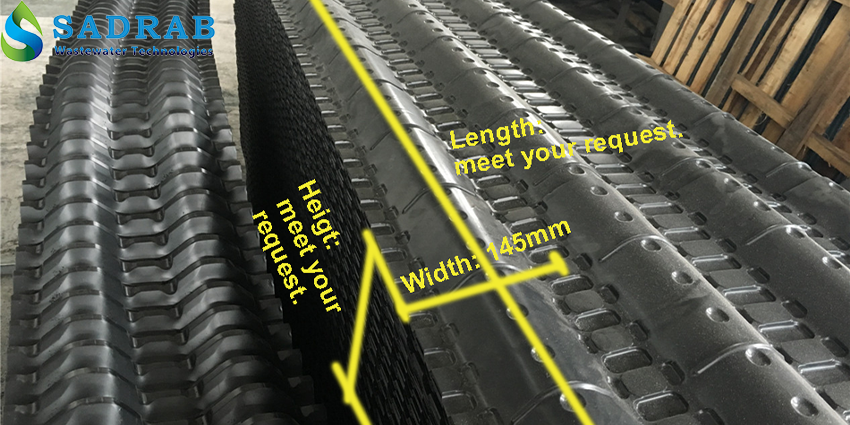

Standard dimensions: Size of 60×60 cm, suitable for various crossflow and counterflow cooling towers.

Lightweight and portable: Low weight for easy installation and handling.

Easy cleaning: Open structure that allows periodic washing and sediment removal.

Temperature resistance: Can withstand high temperatures (up to 90–95°C) for heavy industrial applications.

Types of Sadrab Splash Grid Packing

Sadrab offers Splash Grid Packings in various models:

HP600 Splash Grid Packing: Dimensions 60×60 cm, suitable for industrial cooling towers with contaminated water.

Net Splash Packing: Featuring an advanced design to increase droplet count and improve heat transfer.

Custom Packing: Designed based on specific customer requirements, such as special dimensions or materials.

Applications of Sadrab Splash Grid Packing

Sadrab Splash Grid Packings are used across a wide range of industries and applications:

Petrochemical and Oil Industries: Cooling water in high-volume processes.

Power Plants: Enhancing cooling system performance and reducing energy costs.

Manufacturing Industries: Providing cooling water for production equipment such as machinery and molds.

Commercial Buildings: Used in HVAC systems and cooling units.

Chemical and Food Industries: Managing contaminated water with high salinity.

Advantages of Using Sadrab Splash Grid Packing

Using Sadrab Splash Grid Packing offers multiple benefits:

Enhanced cooling efficiency: Improves heat exchange by up to 30%, reducing outlet water temperature.

Water savings: Cuts make-up water consumption by up to 99% through optimized evaporation.

Reduced energy costs: Improves tower performance, lowering energy use of fans and pumps.

Durability and longevity: Made from resilient materials with a service life of up to 10 years or more with proper maintenance.

Environmental protection: Minimizes water wastage and prevents environmental pollution.

Lower maintenance costs: Anti-scaling design and easy cleaning reduce repair and upkeep expenses.

Installation & Maintenance

Installation:

Sadrab Splash Grid Packings are installed in the middle section of the cooling tower, beneath the water distribution nozzles. Sadrab offers professional installation services to ensure proper placement and optimal performance.

Maintenance:

Periodic cleaning: Wash the packings every 6–12 months to remove scale and algae.

Regular inspection: Check the packing structure for any signs of damage or wear.

Replacement: If performance decreases or degradation occurs, Sadrab provides quick replacement services.

Maintenance tips: Use mild acidic cleaners for washing and avoid excessive water pressure to prevent damage to the packing structure.

Factors for Choosing the Right Splash Grid Packing

When selecting the appropriate packing, consider the following factors:

| Factor | Description |

|---|---|

| Type of Cooling Tower | Crossflow or counterflow towers require different packing configurations. |

| Water Quality | Contaminated or high-salinity water requires more resistant splash grid packing. |

| Airflow Volume | Towers with high airflow demand packings with an open structure. |

| Operating Temperature | The packing must withstand inlet water temperatures (up to 95°C). |

| Maintenance Costs | Durable materials help reduce long-term maintenance expenses. |

Sadrab’s team evaluates your cooling tower conditions to recommend the best packing solution. For a free consultation, contact us.

Sadrab Splash Grid Packing Price

The price of Splash Grid Packing depends on several factors:

Type and model: Net splash models may be more expensive than standard versions.

Size and quantity: Larger packings or bulk orders generally cost more.

Material quality: High-grade polypropylene may increase the overall price.

Installation and maintenance services: Professional installation and maintenance plans may involve additional costs.

For an accurate quote, contact Sadrab’s sales team and take advantage of our special offers!

About Sadrab Caspian Purification Company

The Sadrab Caspian Purification Company is a leading player in Iran’s water treatment and industrial equipment sector, backed by technical expertise and specialized teams in environmental, mechanical, and chemical engineering. With a track record of successful projects across various industries, Sadrab is committed to delivering sustainable and high-quality solutions.

Vision: To be a pioneer in delivering efficient and environmentally friendly industrial equipment.

Values: Quality, innovation, and customer satisfaction.

Services: Consulting, design, manufacturing, installation, and technical support.

Contact us today to start your collaboration with Sadrab!

Conclusion

Sadrab Splash Grid Packing offers an effective solution for optimizing the performance of cooling towers. With enhanced cooling efficiency, reduced water and energy consumption, and environmental protection, these packings deliver significant added value across industries. By providing high-quality packings and professional services, Sadrab is a trusted partner for all your cooling system needs.

To purchase Splash Grid Packing or request expert consultation, contact our team via phone or visit the Sadrab website.

Sadrab — your partner in performance and sustainability.

FAQ

This packing is suitable for both crossflow and counterflow cooling towers. Thanks to its modular design, it can be easily installed in a wide range of tower structures.

Splash Grid Packing breaks water into droplets and distributes it in a splash pattern, making it suitable for contaminated and high-salinity water. In contrast, Film Packing is designed for clean water and provides better surface evaporation but is more sensitive to scaling and fouling.

Simple maintenance is all that’s needed — a gentle wash with water pressure or mild detergent every 6 to 12 months. The open design of the packings makes upkeep very easy.

Made from durable materials like polypropylene and with regular maintenance, these packings can perform optimally for over 10 years in industrial conditions.

Sadrab experts will evaluate your tower type, water quality, operating conditions, and temperature to recommend the best packing model tailored to your needs. Initial consultation is free of charge.