Features of Packing Media:

- High treatment efficiency with large specific surface area

- Excellent chemical resistance to acids and alkalis

- Cost reduction through optimized energy consumption

- Easy installation without the need for complex equipment

- Wide application in both industrial and municipal wastewater treatment

- Long service life using durable raw materials

Specialized support and consulting services

Customized solutions tailored for clients

Guaranteed product quality and performance

Expertise in wastewater treatment technologies

Additional Information:

What is Sadrab Packing Media and why is it important in wastewater treatment?

With the rapid growth of population and industrial development, the need for efficient wastewater treatment systems has become more critical than ever. One of the key components in these systems is packing media, which plays a significant role in enhancing biological treatment processes. Sadrab, with its experience and expertise in manufacturing packing media, offers high-quality and efficient products.

You might find this interesting: Wastewater Treatment Package

What is Packing Media?

Packing media refers to materials used in Sadrab wastewater treatment plants to increase the contact surface between microorganisms and wastewater. This increased contact surface leads to improved biological treatment processes. Packing media are typically made from materials such as PVC, polypropylene (PP), or polyethylene (PE), and are produced in various forms like sheets, blocks, or suspended media. These materials provide a large specific surface area for microorganism growth, which enhances the efficiency of the treatment system.

You can learn more about Sadrab wastewater treatment plants.

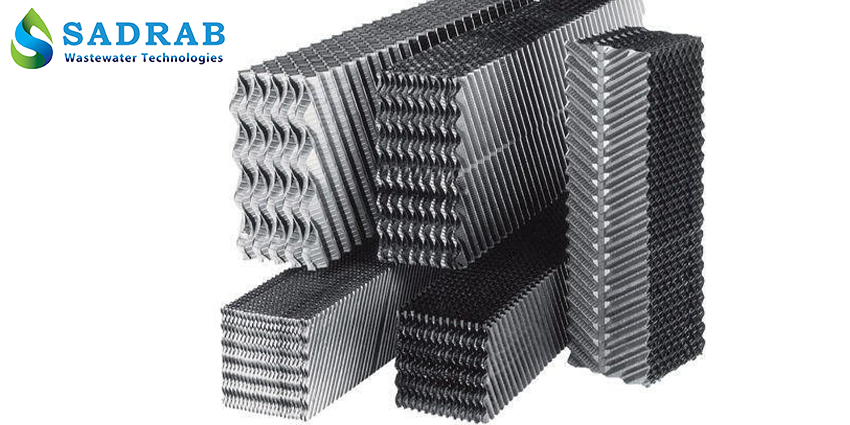

Types of Packing Media Produced by Sadrab

Sadrab produces and supplies two types of packing media:

Fixed Packing Media:

This type is made from high-density polypropylene and is used in fixed-bed attached growth systems. These packings are designed as regular grids or layered sheets, providing an ideal substrate for the growth and multiplication of microorganisms.

Advantages:

Increased contact surface for the growth of treatment bacteria

High resistance to chemicals and impact

Suitable for use in aerobic and anaerobic biological reactors

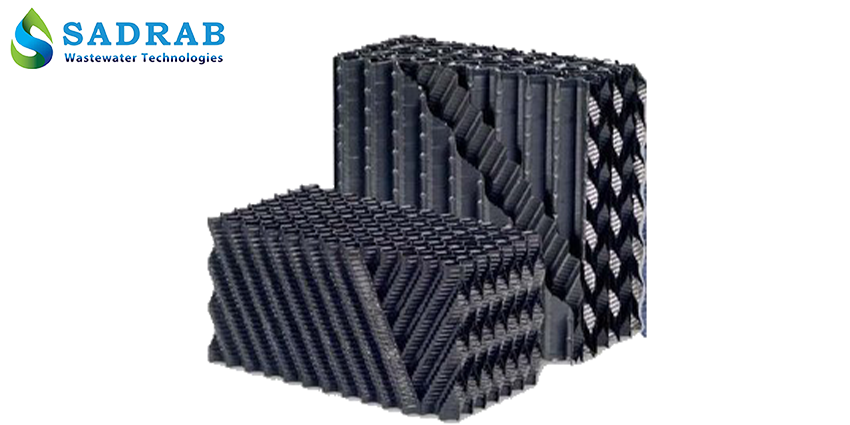

Moving Bed Packing Media (MBBR):

Usually made from polyethylene (PE), these media are used in wastewater treatment systems employing the MBBR (Moving Bed Biofilm Reactor) method. They move freely inside the reactor, improving treatment processes and increasing pollutant removal efficiency.

Advantages:

High specific surface area for microorganism attachment and growth

Continuous flow and reduced clogging in the system

Increased treatment capacity without the need for physical expansion of the treatment plant

Features of Packing Media Produced by Sadrab

🔹 Increased Treatment Efficiency: The high surface area and special structure of the packing media enhance the activity of decomposing bacteria.

🔹 High Chemical and Physical Resistance: Sadrab packings are resistant to acids, alkalis, and corrosive substances, ensuring a long service life.

🔹 Reduced Operating Costs: By optimizing contact surface and removing pollutants, maintenance and energy costs are lowered.

🔹 Easy Installation and Setup: Sadrab packing media can be easily installed in treatment systems without the need for complex equipment.

🔹 Reduced Treatment Tank Size: Due to the increased contact surface, higher treatment capacity can be achieved with smaller tanks.

Applications of Packing Media

The packing media produced by Sadrab are used in various sectors, including:

Municipal and Industrial Wastewater Treatment

Food and dairy industries (removal of organic matter and fats)

Petrochemical and oil industries (removal of hydrocarbon compounds and heavy metals)

Hospital wastewater treatment (reduction of microbial load and pharmaceutical contaminants)

Use in cooling towers (improving heat transfer and increasing the efficiency of cooling towers)

Use in fish farms (treatment and optimization of water quality)

Comparison of Different Packing Media

| Type of Packing Media | Material | Treatment System Type | Specific Surface Area | Chemical Resistance | Durability |

|---|---|---|---|---|---|

| Fixed Packing Media | Polypropylene (PP) | Fixed Attached Growth | Medium | High | Long |

| Moving Bed Packing Media | Polyethylene (PE) | MBBR and IFAS | Very High | High | Long |

| Film Packing | PVC | Aerobic and Anaerobic Systems | High | Medium | Medium |

Why Choose Sadrab Packing Media?

🔸 High-Quality Raw Materials: Using the best industrial polymers to enhance durability and resistance.

🔸 Optimized Design for Wastewater Treatment: Structure providing maximum contact surface and minimal clogging risk.

🔸 Quality Assurance: All products meet the necessary standards for water and wastewater treatment.

🔸 Technical Support and Consultation: Sadrab’s expert team is ready to offer customized solutions for your wastewater treatment needs.

Recommended article: Home Water Purification System

Final Words

Packing media is one of the most important components in wastewater treatment systems, playing a key role in increasing efficiency and improving treatment process performance. Sadrab Company, by producing high-quality packing media and offering innovative solutions, contributes to the enhancement of water and wastewater treatment systems. If you are looking to boost the efficiency of your wastewater treatment plant, Sadrab is the best choice for supplying advanced and durable packing media.

For more information or to place an order, contact the Sadrab team and benefit from the experience and expertise of this company.

FAQ

Packing media increases the contact surface between wastewater and microorganisms, enhancing biological treatment processes and boosting system efficiency.

Fixed packing media remains stationary at the installation site and is suitable for attached growth of microorganisms, while moving packing media moves within the reactor and is used in MBBR (Moving Bed Biofilm Reactor) systems.

The material of packing media depends on the type of treatment system, but polypropylene (PP) and polyethylene (PE) are the most common options due to their high durability and chemical resistance.

Yes, Sadrab’s products are designed and optimized for treating wastewater in municipal, industrial, hospital, food, petrochemical industries, and even cooling towers.