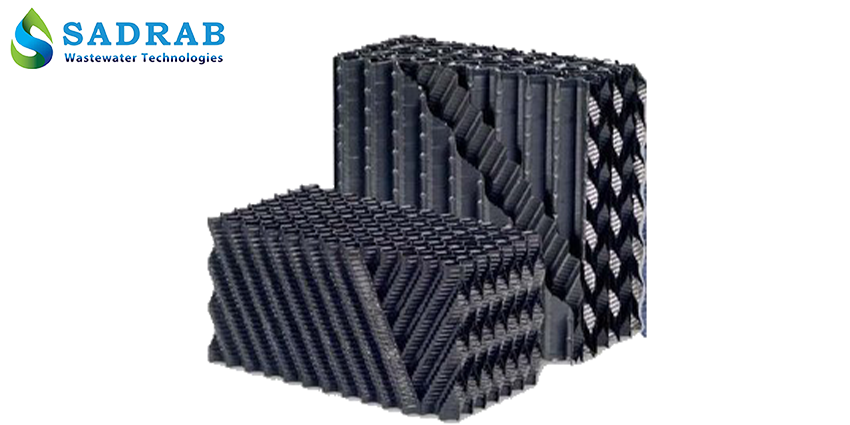

Lamella packing

Features of Lamella Packing:

- Reduced operational costs

- High durability and long lifespan

- Optimization of treatment plant space

- Reduced hydraulic retention time

- Increased sedimentation efficiency

Specialized support and consulting services

Customized solutions tailored for clients

Guaranteed product quality and performance

Expertise in wastewater treatment technologies

Additional Information

Lamella Packing: Key Equipment in Sedimentation of Treatment Plants

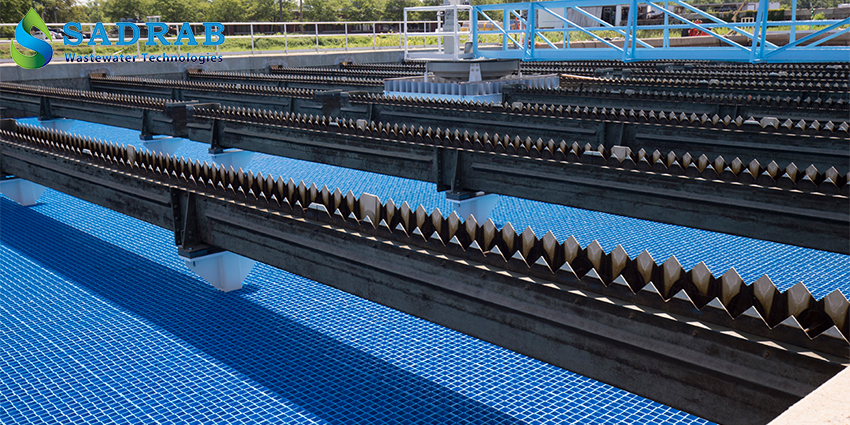

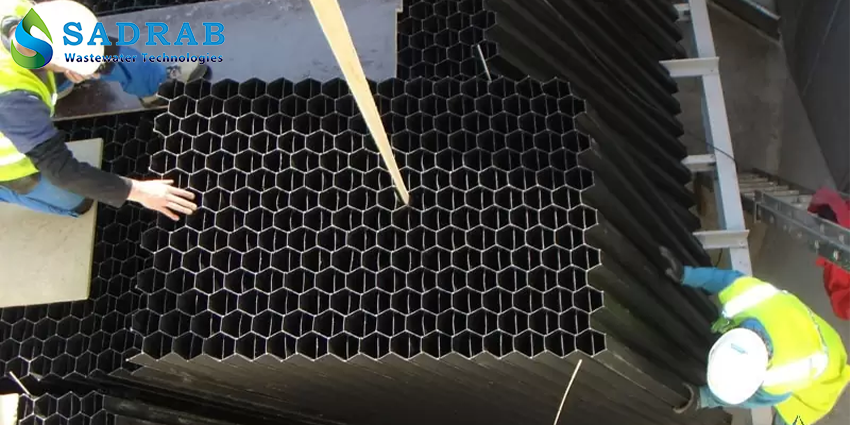

Lamella packing is one of the vital pieces of equipment in the sedimentation process of treatment plants, playing a crucial role in improving the efficiency of water and wastewater treatment. With its unique design, this tool helps optimize the clarification process and the removal of suspended particles, and it is widely used in water and wastewater treatment plants. In this section, we examine the applications, features, and benefits of lamella packing in wastewater treatment equipment and introduce Sadraab as one of the leading manufacturers of this product in Iran.

What is Lamella Packing?

Lamella packing, or lamella plates, is a set of inclined plates installed at a specific angle (usually 45 to 60 degrees) inside sedimentation tanks. These plates change the direction of water or wastewater flow, reducing the velocity of the fluid and shortening the settling time of suspended particles. The result of this process is an increased capacity and efficiency of the treatment plant’s clarifier and the production of clearer effluent.

Due to its honeycomb or corrugated structure, lamella packing provides a larger contact surface for particle sedimentation and prevents sludge and floc escape. This feature has made it widely used in municipal wastewater treatment plants, industrial treatment facilities, and even wastewater treatment packages

Applications of Lamella Packing in Sedimentation of Treatment Plants

Lamella packing is used in various stages of water and wastewater treatment processes and has diverse applications, including:

Increasing Clarification Efficiency:

By installing lamella packing in sedimentation tanks, the effective surface area for suspended particle settling is increased. This helps reduce water turbidity and improves the quality of the treatment plant’s effluent.

Reducing Hydraulic Retention Time:

The design of lamella plates shortens the settling distance for particles, allowing the clarification process to be completed faster and reducing the need for large tanks.

Removal of Grease and Oil:

In gravity grease traps, lamella packing increases the rise rate of free grease particles and enables the removal of particles up to 60 microns, which is highly effective in industrial wastewater treatment.

Optimizing Treatment Plant Space:

Using lamella packing reduces the dimensions of sedimentation tanks, making it ideal for wastewater treatment plants with limited space.

Upgrading Existing Systems:

In units with poor sedimentation performance, installing lamella packing after processes such as aeration or coagulation and flocculation enhances the clarifier’s overall efficiency.

These applications demonstrate that lamella packing is an essential water and wastewater treatment equipment for increasing efficiency and reducing operational costs.

Advantages of Using Lamella Packing in Treatment Plants

Increased Treatment Capacity: By raising the surface loading rate of tanks, lamella packing allows managing a larger volume of municipal or industrial wastewater.

Cost Reduction: Its compact design reduces the need for large and expensive tanks.

High Durability: Lamella plates are usually made from materials like PVC or PP, which are resistant to UV radiation and high temperatures (up to 60°C).

Production of Clear Effluent: By preventing the escape of suspended particles, the quality of the wastewater treatment plant’s effluent is significantly improved.

For more information on suspended particles, you can visit Wikipedia.

The Role of Lamella Packing in Wastewater Treatment Equipment

In wastewater treatment equipment, lamella packing functions as a part of sedimentation systems and is combined with processes such as coagulation and flocculation or biological treatment. This tool is also used in wastewater treatment packages, offering a cost-effective option for both small and large projects by reducing the required time and space. Companies like Sadraab, active in manufacturing lamella packing in Iran, provide this product with high standards tailored to the needs of water and wastewater treatment plants.

Conclusion

Lamella packing has become one of the most widely used water and wastewater treatment equipment by increasing sedimentation efficiency in treatment plants, reducing costs, and improving the clarity of water and wastewater. This tool holds a special place not only in municipal wastewater treatment plants but also across various industries. Sadraab, as one of the manufacturers of this product in Iran, contributes to the development of the wastewater treatment industry by providing high-quality lamella plates.

For more information about lamella packing and to receive consultation on treatment plant equipment, please visit our Contact Us page and benefit from professional solutions.

FAQ

Lamella packing increases the effective sedimentation surface and reduces the distance particles need to settle, making the sedimentation process faster and more efficient. This performance decreases the need for large tanks and, consequently, requires less space for constructing the treatment plant.

Yes, one of the main advantages of lamella packing is its compact design and efficient performance in limited spaces. Therefore, this equipment is an ideal choice for prefabricated wastewater treatment packages, temporary projects, or sites with space constraints.

Lamella plates are typically made from materials such as PVC or PP (polypropylene), which are resistant to corrosion, chemicals, UV radiation, and high temperatures (up to around 60°C). These properties provide high durability and a long service life for the packing even under harsh operating conditions.

In treatment plants with low clarification efficiency, lamella packing can be added as an upgrade to existing systems. Installing these plates after aeration, coagulation, or flocculation stages significantly improves the clarifier’s performance and reduces effluent turbidity—without the need to replace the entire system.