Industrial Water Distillation Unit

Features of Industrial Water Distillation Units

- Utilization of advanced multi-stage technologies

- Very high effluent water quality

- Flexible production capacity

- Robust and industrial structure

- Fully automatic control

- Comprehensive after-sales service support

- Reduction of long-term costs

- Design tailored to industrial spaces

Specialized Support and Consulting Services

Customized Solutions for Clients

Product Quality and Performance Guarantee

Expertise in Wastewater Treatment Technologies

Additional information

Industrial Water Distillation Unit by Sadrab: A Solution for Ultrapure Water Production in Industries

In various industries, access to ultrapure water is a critical need for ensuring product and process quality. Industrial water distillation units are recognized as an efficient solution for removing contaminants and producing high-purity water. Palayesh Sadrab Caspian Company, with over a decade of experience in the water and wastewater treatment industry, offers advanced industrial water distillation units that meet the needs of sensitive industries such as pharmaceuticals, laboratories, and manufacturing. On this page, we will explore the features, technologies, benefits, and how to choose a Sadrab industrial water distillation unit.

What is an Industrial Water Distillation Unit?

An industrial water distillation unit is a piece of equipment that purifies water from impurities, mineral salts, chemicals, and microorganisms using advanced processes like distillation, double reverse osmosis (Double RO), or deionization. These units are designed to produce high-purity water (with an electrical conductivity of less than 2 microsiemens) and are used in industries such as pharmaceuticals, research laboratories, food production, and electronic component manufacturing. The production capacity of these units typically ranges from 250 liters per hour to several thousand liters per day.

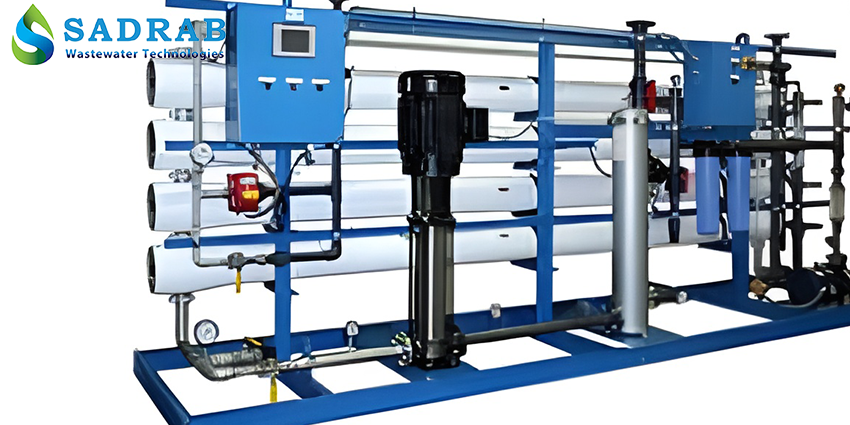

Features of Sadrab Industrial Water Distillation Units

Sadrab offers industrial water distillation units with the following features:

- Advanced Technologies: Utilizes double reverse osmosis (Double RO), distillation, deionization, and ultraviolet (UV) radiation to produce ultrapure water.

- High Capacity: Produces 250 liters to several thousand liters of distilled water per hour, suitable for large industries.

- Robust Design: Features a stainless steel body and metal or glass condensers for long-lasting durability.

- Full Automation: Incorporates electronic control systems for automatic operation and reduced need for operators.

- Effluent Water Quality: Delivers water with an electrical conductivity of less than 2 microsiemens, free from bacteria, viruses, and organic substances.

- After-Sales Services: Provides technical support, valid warranty, and periodic maintenance services.

To order a Sadrab industrial water distillation unit, please contact us!

Technologies Used

Sadrab uses various technologies to produce industrial distilled water:

- Double Reverse Osmosis (Double RO): Removes up to 99.9% of salts, heavy metals, and chemical contaminants in two stages.

- Distillation: Converts water into steam and then cools it to remove impurities that don’t vaporize.

- Deionization: Uses cationic and anionic resins to remove mineral ions.

- Ultraviolet (UV) Radiation: Disinfects water by eliminating microorganisms.

- Activated Carbon Filters: Removes chlorine, organic matter, and unpleasant odors.

These technologies are used either in combination or independently, depending on industry needs and the quality of the incoming water.

Advantages of Sadrab Industrial Water Distillation Units

- High Quality: Produces ultrapure water for sensitive industrial and laboratory applications.

- Economic Savings: Reduces costs associated with purchasing distilled water and increases the lifespan of industrial equipment.

- Environmental Sustainability: Decreases resource consumption and the production of chemical waste.

- Stable Performance: Robust design for continuous operation in industrial conditions.

- Easy Installation and Maintenance: Automatic systems with self-cleaning and descaling capabilities.

- Professional Support: Offers consultation, installation, and specialized repair services by the Sadrab team.

What is an Industrial Water Desalination Unit?

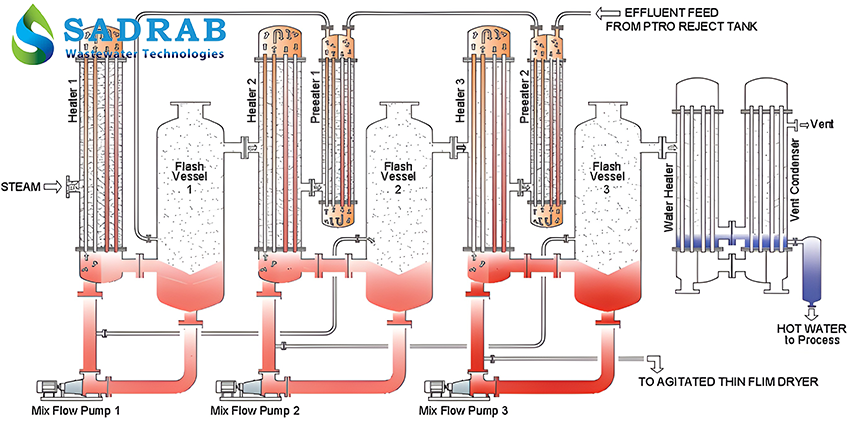

How Sadrab Industrial Water Distillation Units Work

Sadrab units purify water through several distinct stages:

- Pre-treatment: This stage removes large particles, chlorine, and suspended solids using micron and activated carbon filters.

- Double Reverse Osmosis: Here, the system eliminates salts, heavy metals, and chemical contaminants in two successive steps.

- Distillation (if needed): Water is boiled, and the resulting steam is cooled to produce distilled water.

- Deionization: Remaining mineral ions are removed using ion exchange resins.

- UV Disinfection: Microbes and bacteria are eliminated using ultraviolet light to ensure final purity.

- Storage: The purified distilled water is collected in sterile tanks.

These comprehensive stages guarantee that the output water is perfectly suited for both industrial and laboratory applications.

Factors for Choosing an Industrial Water Distiller

To select the appropriate device, consider these factors:

| Factor | Description |

|---|---|

| Input Water Quality | Water with high mineral content requires pre-treatment and Double RO. |

| Production Capacity | 250 liters per hour up to several thousand liters, depending on industrial needs. |

| Required Technology | Double RO, distillation, or deionization depending on the desired purity. |

| Maintenance Cost | Includes replacement of filters, resins, and periodic services. |

| Installation Space | Compact design for industrial environments with limited space. |

Sadrab Industrial Water Distiller Prices

The price of our machines depends on the following factors:

- Technology Type: Advanced Double RO or distillation systems are more expensive.

- Production Capacity: Higher flow rate machines come with a greater cost.

- Additional Features: Such as digital controllers, storage tanks, and automatic washing systems.

- Installation Services: Professional installation and training by the Sadrab team.

For accurate pricing and special offers, please contact the Sadrab sales team!

Maintenance Tips

To ensure your industrial water distiller operates efficiently and has a long lifespan, keep these maintenance tips in mind:

- Filter and Resin Replacement: Change these every 6-12 months, or more frequently depending on the quality of your input water.

- Periodic Cleaning: Descale condensers and tanks using approved materials.

- Water Quality Check: Use a conductivity meter to confirm the purity of the outgoing water.

- Sadrab Services: Benefit from Sadrab’s technical support, specialized repairs, and operator training.

About Sadrab Caspian Purification Company

Sadrab is one of the leading water and wastewater treatment companies in Iran, leveraging its technical expertise and specialized teams in environmental engineering, mechanics, and chemistry. We are committed to providing sustainable solutions through the successful execution of projects across various industries.

Vision: To be a pioneer in supplying pure water for industries and laboratories. Values: Quality, innovation, and customer satisfaction. Services: Consultation, design, manufacturing, installation, and support.

Contact Sadrab today for collaboration!

Conclusion

Sadrab’s industrial water distillers are the ideal solution for providing ultrapure water in sensitive industries. With advanced technologies, robust design, and professional services, Sadrab guarantees the quality and stability of your processes.

To purchase an industrial water distiller or receive consultation, please contact us at our numbers or visit the Sadrab website. Sadrab: Your partner on the path to producing pure water!

FAQ

Sadrab industrial distilled water production devices are designed to produce ultrapure water for industries such as pharmaceuticals, laboratories, food processing, electronics, and other sensitive industries requiring water free of ions, microorganisms, and impurities.

The technologies used include Double Reverse Osmosis (Double RO), Distillation, Deionization, Ultraviolet (UV) Radiation, and Activated Carbon Filters, which can be implemented either in combination or independently, depending on the specific requirements of each project.

The appropriate capacity is determined based on your daily or hourly production needs, the quality of the incoming raw water, and the required volume of ultra-pure water. The Sadrab team conducts an initial analysis and recommends a system tailored to your specific requirements.

Sadrab systems are capable of producing water with electrical conductivity below 2 microsiemens. This high level of purity is ensured through multiple stages of treatment and final disinfection using UV technology.

Maintenance costs include periodic replacement of filters and resins, system cleaning, and monitoring of output water quality. The systems are designed to require minimal operator intervention, ensuring easy and cost-effective maintenance.