Filter Press

Features of Filter Press:

- High solid-liquid separation efficiency in SadrAb Filter Press

- Significant energy savings with advanced design

- Suitable for various industrial and municipal wastewater

- Customizable according to project requirements

- Durable and corrosion-resistant plates with long lifespan

- Easy maintenance and reduced downtime

- Full compatibility with softening and carbon filter systems

- Possibility of automation and intelligent control of the filter press

Expertise in Wastewater Treatment Technologies

Quality Assurance and Product Performance Guarantee

Customized Solutions for Clients

Specialized Support and Consulting Services

Additional Details

Filter Press: A Vital Role in Industrial and Municipal Wastewater Treatment

In today’s world, where water resource management has become a critical issue, the use of modern wastewater treatment technologies is more essential than ever. One of the most powerful tools in this field is the filter press, which plays a key role in separating solids from liquids during the treatment process.

Thanks to its engineered design and diverse capabilities, the filter press is widely used in various industries, including food processing, pharmaceuticals, petrochemicals, and textiles.

What is a Filter Press?

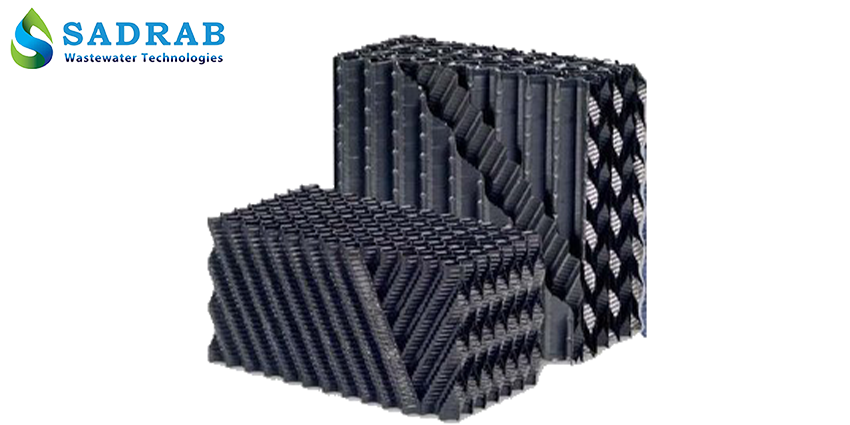

A filter press is a device used to separate solids from liquids in various mixtures. It consists of a series of filter plates that, under high pressure, allow liquid to pass through while retaining solid particles on the surface of the plates. One of the major advantages of a filter press over other separation methods is its ability to produce a very dry solid cake, which makes handling and disposal easier.

In many industries, suspended solids in wastewater can cause serious problems in downstream processes, such as pipe clogging, reduced filtration efficiency, and increased maintenance costs. In such situations, Sadrab’s filter press, with its high efficiency and precision-engineered design, offers a reliable solution for accurate wastewater treatment.

The Importance of Filter Press in Wastewater Treatment Packages

In many wastewater treatment packages, the final filtration or sludge dewatering stage is carried out using a filter press. This device plays a key role in the final stage of biological treatment by removing sludge and suspended solids, thus preparing the effluent for discharge or reuse. The precise and efficient operation of the filter press ensures that the final output is of higher quality.

Additionally, in treatment packages designed for specific industries, the filter press can play a critical role in reducing pollution loads. For instance, in food or pharmaceutical industries where hygiene and accuracy are of greater concern, selecting a filter press that meets international standards is of utmost importance.

The Role of Water Softener Alongside Filter Press

One of the major challenges in the treatment process is the presence of high mineral content and water hardness. Using a water softener can extend the lifespan of the filter press and prevent scale buildup within the system. Minerals such as calcium and magnesium can clog the filter plates and significantly reduce the efficiency of the equipment.

By installing a water softener in the pretreatment stage, not only does the filter press perform better, but maintenance and servicing costs are also greatly reduced. This is especially important in industrial systems with high flow rates.

Carbon Filter: A Perfect Complement to Filter Press

The carbon filter is another essential component in wastewater treatment, primarily used for removing odors, color, chlorine, and volatile organic compounds. It is typically installed before the filter press to prevent non-absorbable particles from entering the system. This step extends the life of the filter plates and enhances the quality of the final filter cake.

In projects where the quality of the final effluent is critical, the simultaneous use of a carbon filter and filter press can significantly improve results. This combination has also been widely implemented in various projects using Sadrab’s advanced treatment technologies.

Industrial Wastewater Treatment Package and the Role of Filter Press

In large-scale industries, the high volume of generated wastewater requires the use of high-capacity, industrial-grade equipment. In such cases, the industrial wastewater treatment package is considered the most efficient solution. These packages include stages such as pre-treatment, biological treatment, and filtration — with the filter press playing a critical role in the final stage.

The use of a filter press in these systems helps reduce the volume of generated sludge and simplifies sludge management. Moreover, its high efficiency enables the treatment of large volumes of wastewater in a short time, making it a competitive advantage for major industrial facilities.

Why Choose Sadrab Filter Press?

Sadrab’s filter press, equipped with cutting-edge technology, high customization capabilities, and premium components, is a reliable solution for a wide range of industries. Its precise engineering, ease of maintenance, and automation options are key features that set Sadrab filter presses apart.

In Sadrab’s implemented projects, the focus has always been on utilizing innovative in-house technology to deliver cost-effective and sustainable solutions. With years of experience in the design, manufacturing, and implementation of water and wastewater treatment systems, Sadrab has earned the trust of numerous industries.

Conclusion

Filter press is one of the most practical tools in industrial and municipal wastewater treatment plants, playing a key role in sludge separation, pollution load reduction, and improving effluent quality. Additionally, equipment such as water softeners, carbon filters, and industrial wastewater treatment packages can significantly enhance the overall system performance.

If you’re looking for a professional, reliable, and cost-effective solution for your industrial wastewater treatment needs, it’s worth taking a look at our completed projects. Perhaps it’s time to consult with our expert team to design and implement a custom treatment system tailored to your operations.

FAQ

The filter press, by applying high pressure and effectively separating solid particles, has the ability to produce a dry cake with very low moisture content. This distinguishes it from methods such as sedimentation or centrifugation.

Yes, in many industrial treatment systems, the filter press is used in combination with water softeners and carbon filters to achieve higher efficiency in contaminant removal and extend the overall system’s lifespan.

Sadrab filter press is suitable for food, pharmaceutical, textile, petrochemical, and many other industries. To receive technical specifications, professional consultation, or a price quote, you can contact the technical consultants of this company.