Aeration Diffuser

Features of Aeration Diffuser:

- Enhanced oxygen transfer for improved biological treatment.

- Reduced energy consumption through optimized design.

- High durability and resistance to chemicals.

- Wide application in treatment plants and various industries.

- Multiple options including fine and coarse bubble diffusers.

Professional support and consulting services

Customized solutions for clients

Quality and performance guarantee of products

Expertise in wastewater treatment technologies

Additional Information

All About Aeration Diffusers | A Complete Guide

In the water and wastewater treatment industry, uniform and effective oxygen supply is one of the most critical steps for maintaining process quality and maximizing system efficiency. The aeration diffuser plays a key role in this process by ensuring efficient oxygen transfer into the water.

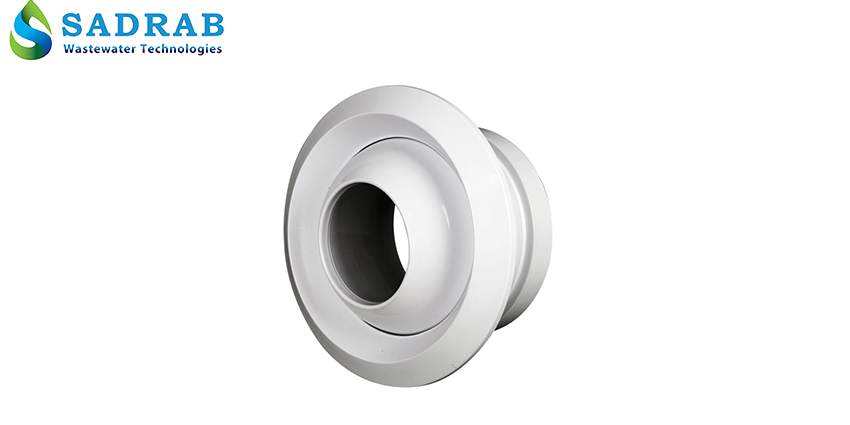

What is an Aeration Diffuser?

An aeration diffuser is a device used to transfer air (or oxygen) into liquids, particularly water. It is commonly installed in wastewater treatment systems to aerate activated sludge or enhance dissolved oxygen levels in water.

The diffuser works by releasing air through fine holes or slits, creating tiny bubbles that disperse throughout the water. The smaller the bubbles, the greater their surface area in contact with water, resulting in more efficient oxygen transfer.

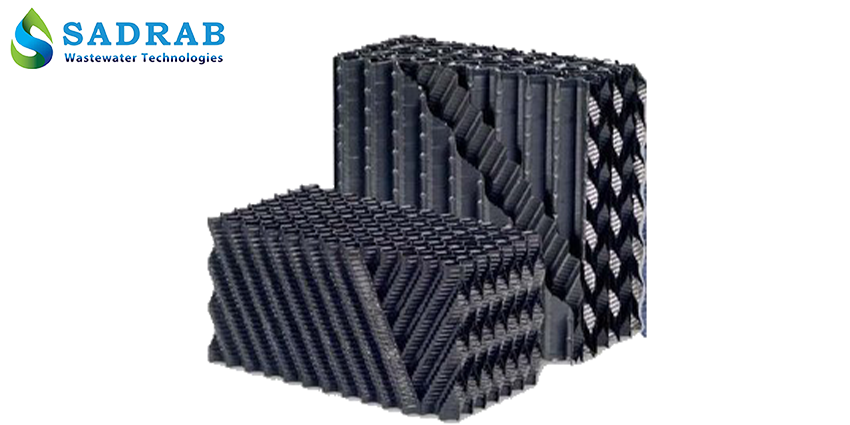

Types of Aeration Diffusers

Diffusers come in various types, each selected based on the application and project requirements. The most common types include:

1.Disk Diffuser

This type of diffuser is designed in a disc shape and typically uses EPDM or silicone membranes. Disc diffusers are among the best-selling types and perform effectively in both municipal and industrial wastewater treatment.

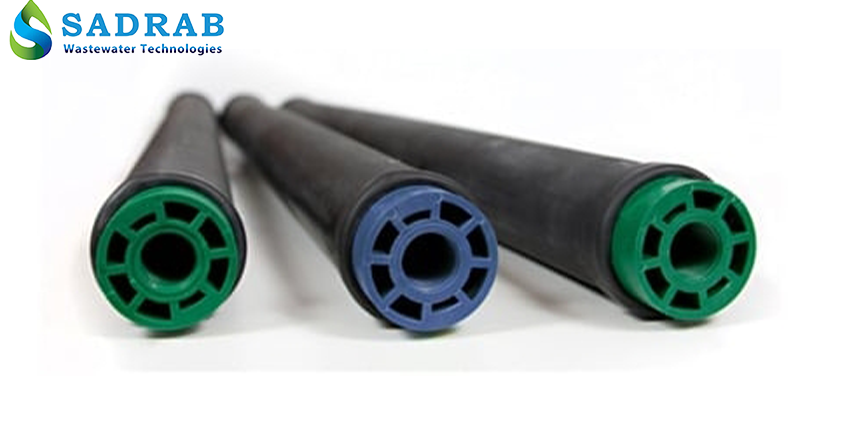

2.Tube Diffuser

Tube diffusers are designed in a cylindrical shape and offer a larger contact surface compared to disc diffusers. They are commonly used in treatment plants with greater depth.

3. Panel Diffuser

This type of diffuser is less common but is used in projects that require wide and uniform air distribution.

Advantages of Using Aeration Diffusers

Using diffusers in aeration systems offers several benefits due to their unique features:

1.Improved Oxygen Transfer Efficiency

Aeration diffusers generate fine bubbles that enable more effective gas exchange between air and water, offering significantly higher efficiency compared to traditional methods.

Energy Savings

By increasing oxygen transfer efficiency, the amount of air required to reach a specific oxygen level is reduced, resulting in lower energy consumption.Easy Installation and Maintenance

Most diffusers are designed for quick and simple installation. In case of repair or replacement, only the membrane needs to be replaced.Long Service Life

By choosing high-quality brands such as those offered by SadrAb, users can rely on the durability and consistent performance of the equipment.Versatile Applications

From municipal and industrial wastewater treatment to aquaculture and irrigation ponds, diffusers are used in a wide range of applications.

Disadvantages of Aeration Diffusers

Despite their numerous benefits, aeration diffusers have certain limitations that should be understood for proper system selection and design:

Need for Proper Air Pressure

If the incoming air pressure is lower than required, bubble distribution will not occur effectively, leading to reduced system performance.Clogging of Membrane Pores

Over time, the membrane’s tiny pores can become clogged due to sediment buildup or fine particles, necessitating cleaning or membrane replacement.Performance Dependent on System Design

If the diffuser layout and positioning are not properly designed, the overall efficiency of the aeration system can be compromised.Higher Initial Cost in Some Projects

Compared to basic aeration methods, diffusers may involve a higher initial investment. However, this is often offset by long-term energy savings and operational efficiency.

Applications of Aeration Diffusers

Municipal wastewater treatment plants

Industrial wastewater treatment

Fish farming and aquaculture systems

Agricultural stabilization and aeration ponds

Research and laboratory centers in the water sector

Why Choose SadrAb Diffusers?

Precision-engineered design for maximum efficiency

Durable membranes resistant to corrosion and chemicals

Easy replacement of parts

Professional consulting, installation, and technical support

Competitive pricing with guaranteed quality

By choosing SadrAb diffusers, you optimize system performance while reducing energy and maintenance costs.

Conclusion

Aeration diffusers are essential components in aeration systems, effectively transferring oxygen into water. Selecting the right diffuser type and manufacturer has a direct impact on treatment quality and overall system efficiency.

Sadrab Company, with its high-quality products and professional services, is ready to meet your diverse needs in this field.

If you are looking for free consultation, a catalog request, or to purchase aeration diffusers with guaranteed quality — contact us. The Sadrab expert team is here to assist you.

Contact Us

To explore our other products and services, visit our website: www.sadrab.com

FAQ

The choice of diffuser type (disc, tube, or panel) depends on factors such as basin depth, air flow rate, type of wastewater or water, and the purpose of aeration. Sadrab’s experts are ready to evaluate your project specifications and recommend the best option.

With proper use and maintenance, diffusers typically last between 3 to 5 years. If you notice a significant drop in aeration performance or severe clogging of the membrane pores, it’s time for replacement.

Yes, the diffuser should be inspected periodically to prevent clogging of the holes or deterioration of the membrane. Using an air filter and maintaining proper pressure can help extend its lifespan.

By using durable materials such as polypropylene and following regular maintenance, these packings can perform effectively for over 10 years under industrial conditions.

Disc diffusers are suitable for shallow to medium-depth tanks and are easier to install, while tubular diffusers offer a larger diffusion area and are recommended for environments with higher volumes or greater depths.