Design and Implementation of Textile Industry Wastewater Treatment Plant

Features of Designing and Implementing Textile Industry Wastewater Treatment Plants:

- Ability to remove over 95% of resistant and complex textile dyes

- Significant reduction of COD and BOD in compliance with environmental standards

- Custom design based on dyeing type (reactive, disperse, direct, etc.)

- Capability to recycle 70–80% of treated water back into the production line

- Prefabricated, modular package installable in limited spaces

- Use of automated systems for pH control, dosing, and retention time

- Expandable capacity and compatibility with future advanced equipment

- Customized design with minimal sludge generation

Specialized Support and Consulting Services

Customized Solutions Tailored to Client Needs

Guaranteed Product Quality and Performance

Expertise in Wastewater Treatment Technologies

Additional Information

Professional Solutions for Textile Industry Wastewater Treatment: In-Depth Review and Analysis

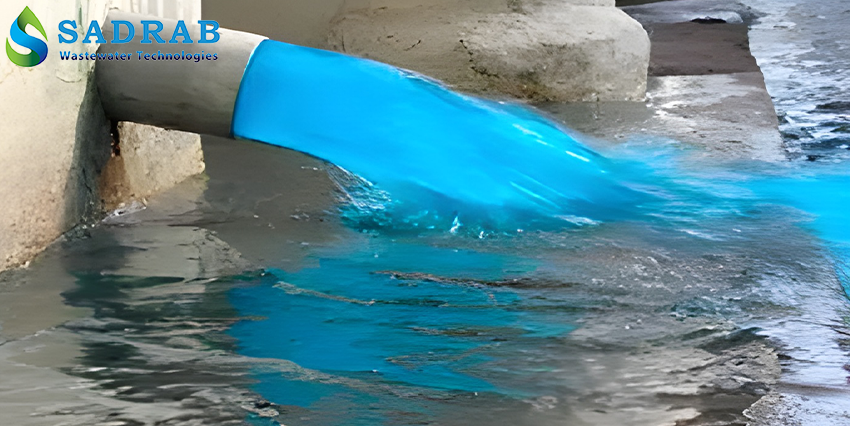

The textile industry, due to its extensive use of water and chemical substances, produces complex wastewater that requires advanced treatment solutions. Effective management of textile wastewater not only ensures compliance with environmental standards but also helps conserve water resources.

In this article, we examine various aspects of textile wastewater treatment from a technical perspective, analyze practical methods for treating textile effluents, and evaluate solutions such as textile wastewater treatment units and prefabricated treatment packages for the textile industry.

Textile Industry Wastewater Treatment: Challenges and Necessities

Textile wastewater treatment is a challenging process due to the presence of synthetic dyes, chemical substances such as alkalis and acids, and organic materials in the textile industry effluent. This wastewater, with high COD and BOD levels, intense color, and variable pH, poses a serious environmental threat without proper textile wastewater treatment. Textile units must apply practical textile wastewater treatment methods to comply with legal requirements and reduce environmental impacts.

Using textile wastewater treatment units is a key solution to improve the quality of textile effluents. These advanced systems remove pollutants and enable water recycling in textile processes. Through effective wastewater management in the textile industry, companies can achieve greater sustainability.

You might find this interesting: Honeycomb Drip Tray Model TEP125

Textile Wastewater Treatment: Advanced and Innovative Approaches

Treating textile industry wastewater requires technologies that can tackle the resistant compounds found in textile effluents. Textile wastewater treatment often faces challenges in removing stable organic dyes, surfactants, and heavy metals. In this context, biological treatment of textile wastewater using microorganisms breaks down organic matter and reduces pollutant load but requires complementary methods for complete decolorization.

Prefabricated wastewater treatment packages for the textile industry are an ideal solution for treating textile effluents. These packages, designed as ready-made units, offer quick installation and efficient performance, making them highly suitable for small to medium textile facilities. By employing practical textile wastewater treatment methods, this process becomes a sustainable and economical system.

Textile Industry Wastewater: Characteristics and Environmental Issues

Wastewater from the textile industry, due to processes such as dyeing, washing, and fabric finishing, contains suspended solids, persistent dyes, and toxic chemical substances. Without proper management of textile wastewater, these pollutants threaten aquatic ecosystems and impose additional costs on textile facilities. Treating textile wastewater is essential to mitigate these risks.

Practical methods for treating textile effluents include chemical, physical, and biological processes that reduce pollution from textile industry wastewater. The use of textile wastewater treatment units also helps remove dyes and toxic substances, minimizing the environmental impact of textile effluents. These solutions enable safe disposal or recycling of water.

Recommended Article: Trash Rack (Screening Device)

Practical Methods and Stages of Textile Wastewater Treatment

Textile wastewater treatment involves stages and methods, each playing a vital role in removing pollutants from textile industry effluents. Below, these stages and practical treatment methods are analyzed:

Pre-treatment:

In this stage, suspended solids and particles are removed using textile wastewater treatment equipment equipped with filtration or flotation systems. This is the initial step in textile wastewater treatment.

Chemical Treatment:

Coagulation and flocculation using chemicals such as aluminum sulfate reduce dyes and COD in textile effluents. This method is considered one of the practical textile wastewater treatment techniques.

Biological Treatment:

Biological treatment of textile wastewater, using processes like activated sludge, removes biodegradable organic matter and reduces BOD in textile effluents.

Advanced Treatment:

Methods such as adsorption with activated carbon, advanced oxidation, and membrane processes (like reverse osmosis) are used to remove dyes and heavy metals from textile wastewater. These technologies are implemented in advanced textile wastewater treatment packages.

Recycling and Disposal:

After treatment, the textile effluent is either recycled for reuse in textile processes or safely disposed of, aiding effective textile wastewater management.

You might find this interesting: What is a Deionizer and How Does It Work?

Conclusion

The best solutions for treating textile wastewater and textile industry effluents are key priorities in this sector. By utilizing practical textile wastewater treatment methods and advanced equipment such as textile wastewater treatment units and prefabricated treatment packages, efficient and sustainable solutions can be achieved. Whether your goal is to reduce pollution from textile wastewater or optimize textile effluent treatment processes, selecting the appropriate technology is essential for success.

For free consultation and professional solutions in textile wastewater treatment, contact Sadrab Company .

09119191911

We are ready to implement the best wastewater management systems for the textile industry for you.

FAQ

Yes, in many cases, the treated water is of sufficient quality to be used for rinsing, initial washing, or even in re-dyeing processes, depending on the designed treatment level.

Yes. The treatment packages are designed to be modular and scalable, allowing for upgrades or modifications if there are changes in dye type, fiber, or wastewater volume.

Sadrab Company offers compact prefabricated packages that can be installed in minimal spaces, including containerized setups or rooftop installations, without the need for extensive construction.