Design and Implementation of a Treatment Plant for Mineral Industries

Design and Implementation Features of a Wastewater Treatment Plant for Mineral Industries

- High-efficiency removal of Total Suspended Solids (TSS)

- Modular and prefabricated design

- Capability of recycling treated water back into the production line

- Smart pH control and chemical dosing system

- Environmentally friendly and compliant with Iran Department of Environment standards

- Equipped with final filtration system (e.g., sand or disc filters)

- Capability to remove heavy metals from mining wastewater

- Upgradeable for increased capacity or additional treatment stages

Expertise in Wastewater Treatment Technologies

Guaranteed Product Quality and Performance

Customized Solutions Tailored to Client Needs

Support and Consulting Services

Additional Information

Professional Solutions for the Treatment of Mineral and Sand & Gravel Industry Wastewater: A Technical Review

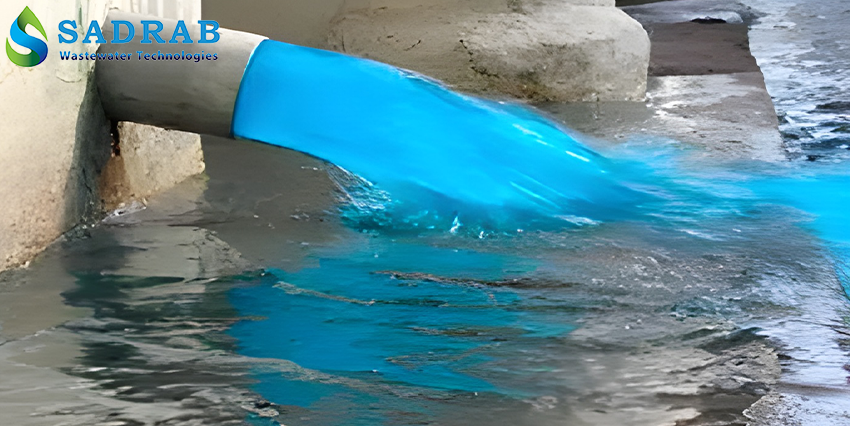

Mineral and sand & gravel industries generate wastewater with specific characteristics due to extraction, washing, and material processing operations. These effluents require advanced treatment solutions to meet environmental regulations and conserve valuable water resources.

This article explores various aspects of wastewater treatment in the mineral and sand industries, analyzing practical approaches with a focus on Chemical Treatment Systems such as coagulation and flocculation. It also highlights Sadrab Company’s expertise in designing and implementing industrial treatment plants in this field.

In addition, we assess solutions like mineral wastewater treatment units and packaged treatment systems for mineral and sand & gravel industries, providing insights into their efficiency and adaptability.

Wastewater Treatment for Mineral and Sand & Gravel Industries: Challenges and Necessities

Treating wastewater from mineral and sand & gravel industries is a complex process due to the presence of suspended solids, mineral sediments, and heavy metals in their effluents. This wastewater, characterized by high turbidity, Total Suspended Solids (TSS), and sometimes chemical pollutants, can contaminate water and soil if not properly treated. Mineral facilities must employ practical mineral wastewater treatment methods to comply with environmental regulations and minimize negative impacts.

Using mineral wastewater treatment units is a key solution to improve the effluent quality of mineral and sand & gravel industries. Sadrab Company, with extensive experience in designing and implementing industrial treatment plants, offers these systems equipped with advanced technologies to remove pollutants and enable water recycling. Through effective management of mineral and sand & gravel wastewater, Sadrab contributes to the sustainability of these industries.

Wastewater Treatment in Mineral and Sand & Gravel Industries: Advanced Approaches

Wastewater treatment for mineral and sand & gravel industries requires technologies that effectively address the unique characteristics of their effluents. Treating wastewater from these industries often involves challenges related to the removal of fine particles and sediments, where chemical and physical processes play a crucial role. While biological treatment of mineral wastewater has limited application, chemical systems such as coagulation and flocculation provide higher efficiency.

Packaged wastewater treatment systems for mineral and sand & gravel industries offer an efficient solution for treating their effluents. Sadrab Company, by designing these prefabricated packages, delivers solutions with rapid installation and high performance, ideal for mineral and sand production facilities. Utilizing practical mineral wastewater treatment methods, Sadrab transforms this process into an effective and economical system.

Wastewater from Mineral and Sand & Gravel Industries: Characteristics and Environmental Issues

Wastewater from mineral and sand & gravel industries contains suspended solids, silt, and sometimes heavy metals due to stone washing, crushing, and grading processes. Without proper wastewater management in these industries, these pollutants contaminate rivers and groundwater, causing additional costs for the facilities. Therefore, treating wastewater from mineral and sand & gravel industries is essential to mitigate these risks.

Practical mineral wastewater treatment methods include chemical processes and sedimentation that reduce contamination in the effluent of mineral and sand & gravel industries. Sadrab Water Treatment Technology Company, with unique expertise in designing and implementing industrial treatment plants, offers customized solutions for removing these pollutants. Utilizing mineral wastewater treatment units by Sadrab reduces turbidity and minimizes the environmental impacts of wastewater from mineral and sand & gravel industries.

Practical Methods and Stages of Wastewater Treatment for Mineral and Sand & Gravel Industries with a Focus on Coagulation and Flocculation

Wastewater treatment for mineral and sand & gravel industries involves several stages and methods, each playing a crucial role in removing pollutants from the effluent. Given the characteristics of this wastewater, chemical treatment systems—particularly coagulation and flocculation—offer higher efficiency. Below, these stages and practical treatment methods are analyzed:

Pre-treatment:

Large suspended particles are removed using mineral wastewater treatment units equipped with sedimentation or flotation. This initial step is essential to prepare the wastewater from mineral and sand & gravel industries for subsequent processes.

Chemical Treatment: Coagulation and Flocculation:

Coagulation and flocculation are the most important methods in treating wastewater from mineral and sand & gravel industries. In this process, coagulants such as aluminum sulfate or ferric chloride are added to the wastewater to bind fine and colloidal particles together, forming larger flocs. These flocs are then separated by sedimentation or filtration.

Advantages: High speed, removal of non-settleable particles, and effectiveness in large volumes of mineral and sand & gravel wastewater.

Sadrab’s Role: Sadrab Company designs coagulation and flocculation systems in industrial treatment plants, implementing this method with high precision. These systems are integrated into Sadrab’s packaged wastewater treatment plants for mineral and sand & gravel industries.

Advanced Controls: Using mineral wastewater treatment units equipped with automatic pH control and dosing systems, Sadrab optimizes the coagulation process and effectively removes TSS and heavy metals.

Supplementary Filtration:

After coagulation and flocculation, filtration (such as sand filters) removes remaining particles from the wastewater. Sadrab enhances this step in its treatment plant designs to improve the quality of treated wastewater.

Advanced Chemical Treatment:

To remove heavy metals or specific chemicals in mineral and sand & gravel wastewater, Sadrab employs processes like precipitation and ion exchange, complementing coagulation and flocculation.

Biological Treatment (Limited):

Biological treatment of mineral wastewater is applied in specific cases involving biodegradable organics but is less common in this industry.

Recycling and Disposal:

After treatment, the water is either recycled for mineral washing or discharged. Sadrab designs recycling systems within industrial treatment plants to support effective wastewater management in mineral and sand & gravel industries.

Sadrab Company’s Capabilities in Designing and Implementing Industrial Treatment Plants

As a pioneer in the field of wastewater treatment for mineral and sand & gravel industries, Sadrab Company possesses unique capabilities in designing and implementing industrial treatment plants. Relying on engineering expertise and extensive experience, the company offers customized systems for treating wastewater from mineral and sand & gravel industries, including:

Specialized Design: Sadrab designs treatment plants focused on coagulation and flocculation processes tailored to the specific characteristics of mineral and sand & gravel wastewater.

Advanced Implementation: Utilizing mineral wastewater treatment units and packaged treatment systems for mineral and sand & gravel industries, Sadrab executes projects with speed and precision.

Comprehensive Support: Sadrab’s after-sales services and maintenance ensure the long-term performance of wastewater treatment systems for mineral and sand & gravel industries.

These capabilities make Sadrab a trusted partner for mineral processing and sand & gravel production facilities.

Conclusion

The Best Solutions for Wastewater Treatment in Mineral and Sand & Gravel Industries

Treating wastewater from mineral and sand & gravel industries is a top priority in this sector. By focusing on practical mineral wastewater treatment methods such as coagulation and flocculation, and utilizing advanced equipment like mineral wastewater treatment units and packaged treatment systems for mineral and sand & gravel wastewater, efficient solutions can be achieved. Sadrab Company, with its outstanding capabilities in designing and implementing industrial treatment plants, optimizes this process and reduces pollution from mineral and sand & gravel wastewater.

For free consultation and professional solutions in mineral and sand & gravel wastewater treatment, contact Sadrab Company at:

09119191911

We are ready to implement the best wastewater management systems for your mineral and sand & gravel facilities.

FAQ

A Mineral Wastewater Treatment Unit is typically a standalone unit designed to perform one or several specific treatment steps (such as sedimentation or filtration). In contrast, a Treatment Package is a complete, integrated system that includes multiple treatment processes (like pre-treatment, coagulation, flocculation, filtration, and recycling) and is designed for comprehensive and continuous treatment.

Yes. Besides removing suspended and colloidal particles, this process can effectively reduce heavy metals such as iron, manganese, and lead by forming precipitates—especially when combined with precise pH adjustment and the addition of complementary chemicals.

Absolutely. The systems designed by Sadrab enable the recycling of treated water. This reduces the consumption of raw water, lowers costs, and enhances environmental sustainability in the production facility.

Biological treatment is applicable when the wastewater contains biodegradable organic matter (such as oils or organics of human origin). However, in most cases, mineral industry wastewater mainly consists of mineral particles, so this method has limited application.

Depending on the capacity and type of the project, the design and manufacturing process takes between 2 to 6 weeks. Installation and commissioning typically require 2 to 5 working days. Sadrab offers fast on-site installation services.