Design and Implementation of Dairy Industry Wastewater Treatment Plants

Features of Designing and Implementing Wastewater Treatment Plants for the Dairy Industry:

- Customized design based on the type of dairy wastewater

- Use of MBBR and MBR technologies

- Professional pretreatment for removal of fats and solids

- Significant reduction of BOD and COD in dairy wastewater

- Possibility of recycling treated water in industrial lines

- Successful projects for major dairy brands (Kalleh, Dalah Shomal)

- Full support from consultation to operation

- Reduction in energy consumption and operational costs

Specialized support and consulting services

Customized solutions tailored for clients

Guaranteed product quality and performance

Expertise in wastewater treatment technologies

Additional Information:

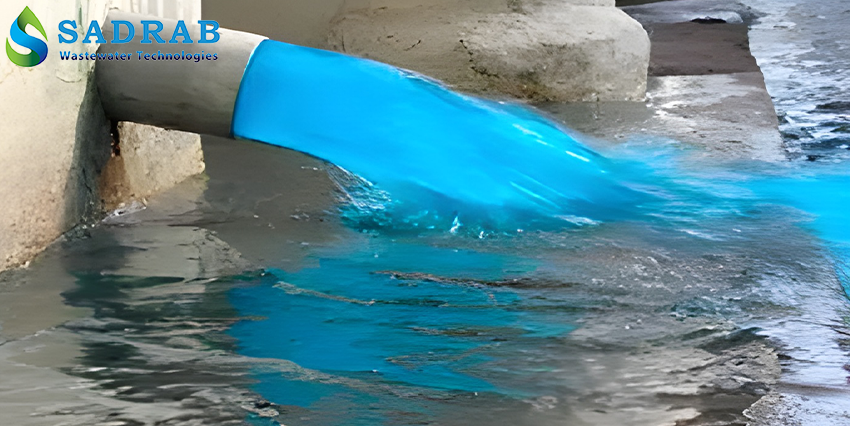

Design and Implementation of Dairy Industry Wastewater Treatment Plants by Sadrab

Dairy industries, due to their high water consumption and production of wastewater with a high organic load, are among the most challenging sectors in wastewater management. Treating wastewater from these industries is not only essential for environmental protection but also helps reduce costs and enables water reuse. Sadrab Caspian Treatment Company, with over a decade of experience in the water and wastewater treatment industry, offers advanced and sustainable solutions for the design and implementation of dairy industry wastewater treatment plants. By utilizing modern technologies and a specialized team, we assist dairy industries in managing their wastewater responsibly and efficiently.

Challenges of Dairy Industry Wastewater Treatment

The wastewater from dairy industries has unique characteristics that make its treatment complex:

High organic load: Contains large amounts of fats, proteins, and carbohydrates, leading to high BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) levels (up to 8000-10,000 mg/L).

Rapid biodegradability: Organic materials quickly decompose, causing odor and pollution.

Chemicals: Includes detergents and disinfectants used in cleaning-in-place (CIP) processes.

pH fluctuations: Changes in pH due to production and cleaning processes.

Whey: One of the most challenging components of dairy wastewater with very high BOD and COD.

These characteristics require advanced treatment systems and precise design, challenges that Sadrab addresses with its expertise.

Sadrab’s Expertise in Dairy Industry Wastewater Treatment

Sadrab Company, with a brilliant track record in designing and implementing wastewater treatment plants, has successfully completed projects for major dairy companies such as Kaleh and Dalleh Shomal. With a deep understanding of the dairy industry’s needs, we provide customized solutions that:

Comply with the standards of Iran’s Department of Environment (DOE).

Reduce operational costs.

Enable the reuse of treated water.

Sadrab’s expert team, consisting of environmental, mechanical, and chemical engineers, guarantees the best performance using state-of-the-art technologies.

Technologies Used

Sadrab employs advanced technologies for treating dairy industry wastewater. Some of these technologies include:

MBBR (Moving Bed Biofilm Reactor):

This technology uses moving plastic media that provide a large surface area for microorganisms to grow and break down organic matter. MBBR is highly suitable for wastewater with high organic load.

MBR (Membrane Bioreactor):

A combination of biological treatment and membrane filtration that produces high-quality effluent, ideal for reuse.

Extended Aeration Activated Sludge:

A traditional but effective biological method for reducing BOD and COD.

Physical-Chemical Pretreatment:

Includes screening, grease separation, and sedimentation to remove suspended solids and fats before biological treatment.

These technologies are used individually or in combination depending on the wastewater characteristics and customer needs.

Design and Implementation Process of Wastewater Treatment Plant

Sadrab carries out the design and implementation process of wastewater treatment plants with precision and expertise:

Wastewater Analysis:

The characteristics of wastewater (pH, BOD, COD, TSS) and the daily production volume are analyzed.Technology Selection:

Suitable technologies are chosen based on the wastewater analysis and environmental standards.Detailed Design:

The layout of the treatment plant, retention time calculations, and equipment selection are done according to industrial standards.Construction and Installation:

Structures and equipment are built and installed under the supervision of Sadrab engineers.Commissioning and Testing:

The system is started up and its performance is evaluated through quality tests.Training and Support:

Operators are trained and after-sales services are provided for optimal operation.

Benefits of partnering with Sadrab

Compliance with standards:

Ensuring wastewater treatment in accordance with environmental regulations.

Cost reduction:

Optimizing water and energy consumption with low-energy technologies.

Environmental sustainability:

Reducing pollution and enabling reuse of treated water.

Comprehensive support:

From initial consultation to long-term maintenance, Sadrab is by your side.

Successful experience:

Projects completed for reputable brands such as Kalleh and Dalah Shomal

Comparison Table of Wastewater Treatment Technologies

| Technology | Application | Advantages | Disadvantages |

|---|---|---|---|

| MBBR | Biological treatment | Easy maintenance, high capacity | Higher initial cost |

| MBR | Advanced treatment | High output quality, water reuse possible | High operational cost |

| Activated Sludge | Organic matter reduction | High efficiency, moderate cost | Requires energy for aeration |

| Chemical Pre-treatment | Removal of fats and solids | Simple and effective | Requires chemicals |

Contact Sadrab

Are you looking for an efficient solution to manage wastewater in your dairy industry? The Sadrab team is ready to support you by offering free consultations and designing customized systems. For more information or to request services, contact us or visit the Sadrab website.

Conclusion

Sadrab Caspian Refining Company, with extensive experience and advanced technologies, offers ideal solutions for dairy industry wastewater treatment. With a commitment to quality, innovation, and sustainability, we help you manage your wastewater responsibly and achieve your environmental and economic goals. To start your project, contact Sadrab today!

FAQ

The engineering team at Sadrab conducts precise wastewater analysis, evaluates site conditions, and reviews your industry’s specific needs to select and design the best treatment technology (such as MBBR, MBR, activated sludge, or reverse osmosis).

Yes. Sadrab offers comprehensive support services including operator training, provision of technical documentation, periodic maintenance, and system updates to ensure continuous and optimal performance of the treatment plant.

Yes, by using technologies such as MBR (Membrane Bioreactor) and Reverse Osmosis, the quality of treated water reaches a level that allows it to be reused in industrial applications such as washing, cooling towers, or even some production processes.