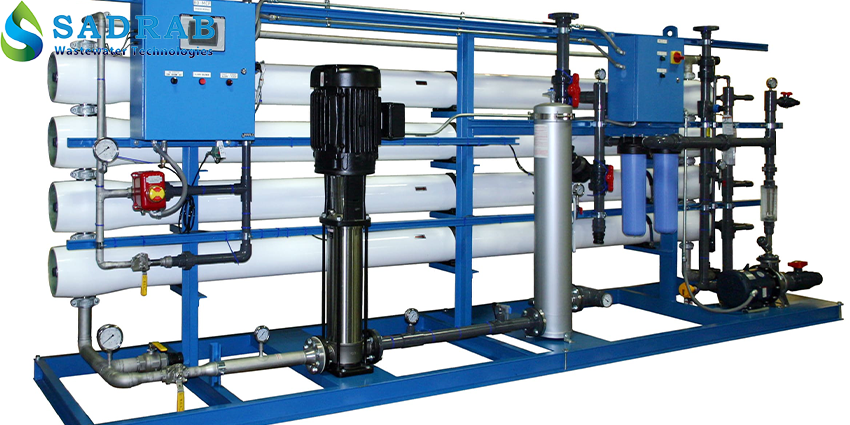

Chemical Treatment Package

Features of the Chemical Treatment Package:

- Adjustable for various industries (textile, metal, food, petrochemical)

- Fast and effective removal of color, heavy metals, and suspended solids

- Use of high-quality and standard chemicals (Alum, PAC, Ferric, Polymer)

- Smart process control and automation via PLC panel or basic controller

- Optimized design for minimal space usage (suitable for indoor or outdoor installation)

- Corrosion-resistant body (made of stainless steel, polyethylene, or fiberglass with anti-acid coating)

- Can be installed inline with production or as a pretreatment before biological units

Expertise in advanced wastewater treatment technologies

Guaranteed product quality and performance

Customized solutions tailored to client needs

Expert support and consultation services

Additional Information

Chemical Wastewater Treatment: An Effective Solution for Managing Industrial Effluents

Chemical wastewater treatment is a widely used method for removing pollutants from industrial wastewater, specifically designed for heavy effluents. This process uses chemical wastewater treatment packages, such as the systems provided by sadrab, to eliminate contaminants like suspended solids, colored substances, and dissolved compounds. This article reviews the chemical wastewater treatment process, including coagulation and flocculation stages, the chemicals used, and its applications in various industries, highlighting the role of reputable companies like sadrab in offering modern wastewater treatment solutions.

What is a Chemical Treatment Package?

Industrial wastewater contains pollutants such as heavy metals, colored substances, and suspended particles that pose significant environmental and health challenges. Chemical wastewater treatment through coagulation and flocculation provides an effective solution to remove these contaminants in industries like textile, petrochemical, and metal processing. Chemical wastewater treatment packages, such as those designed by sadrab, utilize advanced technologies to enable efficient management of chemical wastewater treatment. This article explains the chemical wastewater treatment process, its stages, and practical applications.

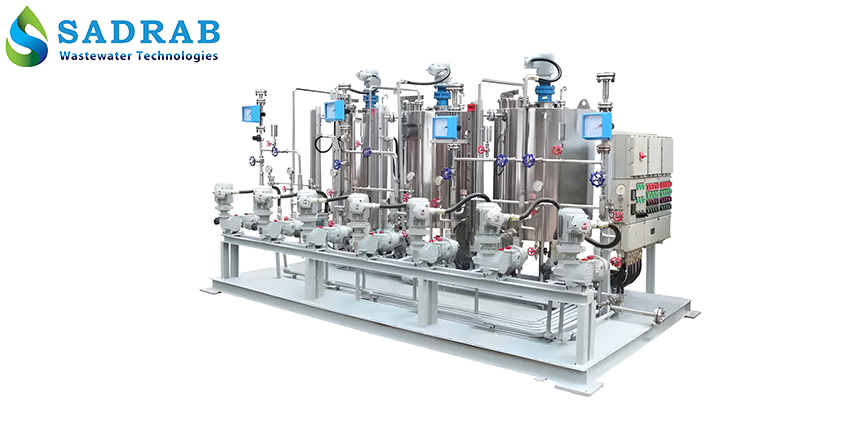

Chemical Wastewater Treatment Process

Chemical effluent treatment using coagulation and flocculation involves two main stages executed within the chemical wastewater treatment package:

Coagulation

During coagulation, specific chemicals are added to the wastewater to destabilize suspended and colloidal particles. These particles usually remain suspended due to their negative electric charge. Adding substances like aluminum sulfate or ferric chloride neutralizes this charge and prepares the particles for sedimentation. Rapid mixing in sadrab’s chemical wastewater treatment package (15–30 seconds at high speed) ensures uniform distribution of chemicals throughout the wastewater.Flocculation

After coagulation, the flocculation stage occurs with slow mixing (10–30 minutes at low speed). In this phase, destabilized particles bind together forming larger aggregates called flocs, which can be easily settled or filtered. The use of coagulant aids like polymers in sadrab’s chemical wastewater treatment package helps create stable flocs.

Chemicals Used in Chemical Wastewater Treatment

The chemicals used in chemical wastewater treatment include the following:

Aluminum sulfate (Alum): for removing suspended particles and reducing wastewater turbidity.

Ferric chloride: for removing dissolved compounds such as heavy metals.

Poly Aluminum Chloride (PAC): for forming larger flocs and improving the efficiency of chemical wastewater treatment.

Coagulant aids (Polymers): to enhance the flocculation process.

sadrab optimizes the process efficiency by selecting suitable chemicals in its chemical wastewater treatment packages.

For more information or to order a package, contact the sadrab team and benefit from the experience and expertise of this company.

Factors Affecting the Efficiency of Chemical Wastewater Treatment

The following factors influence the success of chemical wastewater treatment:

Wastewater pH: Adjusting the pH to an appropriate range (such as 6.5-7.5 for alum) is essential for optimal chemical performance.

Chemical dosage: The correct amount of chemicals is determined through practical testing.

Mixing: The speed and duration of mixing in the chemical wastewater treatment package affect the quality of flocculation.

Temperature: A temperature range of 5-40°C is suitable for chemical wastewater treatment.

Process Optimization Testing

To optimize chemical wastewater treatment, tests are conducted that include adding different chemical dosages to wastewater samples, rapid and slow mixing, and evaluating floc formation and sludge volume. sadrab uses this method in their chemical wastewater treatment packages to achieve the best results.

Applications of Chemical Wastewater Treatment

Chemical wastewater treatment in treatment packages is applied in the following industries:

Textile industry: Removal of colored substances from wastewater.

Petrochemical industry: Removal of grease and oil from effluents.

Metal industry: Removal of heavy metals.

Food industry: Reduction of organic pollutant load.

sadrab provides chemical wastewater treatment packages with solutions tailored to the needs of these industries.

Advantages of Chemical Treatment Packages

Effective removal of pollutants in wastewater treatment.

Flexibility of chemical wastewater treatment packages for various industrial wastewaters.

Cost-effective compared to more advanced methods.

Disadvantages of Chemical Treatment Packages

Sludge production, which requires proper management.

Need for precise adjustment of process conditions in chemical wastewater treatment.

Conclusion

Chemical wastewater treatment using the chemical treatment packages provided by sadrab is an efficient method for managing industrial wastewater. This technology helps protect the environment by removing complex pollutants. Process optimization through selecting appropriate chemicals and adjusting operational conditions enhances the efficiency of chemical wastewater treatment.

If you need expert guidance for selecting or implementing a chemical wastewater treatment package, our specialists at sadrab are ready to assist you.

For more information or to submit a request, please visit the Contact Us page.

FAQ

Yes, these packages are specifically designed for industrial wastewater containing pollutants such as heavy metals, colored substances, oils, and dissolved compounds. However, in some special cases, they can also be used for non-industrial wastewater, but the choice of treatment method should be carefully evaluated based on the type of pollutants.

Common chemicals include aluminum sulfate (alum), ferric chloride, PAC, and polymer coagulant aids. These materials are used in controlled doses based on the type of wastewater. When the system is properly designed and standards are followed, their use is completely safe.

In chemical treatment, a certain amount of chemical sludge is produced, which varies depending on the type and volume of wastewater. The sludge must be safely collected, dewatered, and disposed of or transferred to authorized sludge disposal centers. sadrab also considers sludge management in the design of the treatment package.

Yes, by precisely adjusting the pH, chemical dosage, mixing time, and selecting the right flocculants, system efficiency can be increased. The technical team at sadrab conducts advanced tests (jar tests) to determine the optimal operating conditions for each industry.