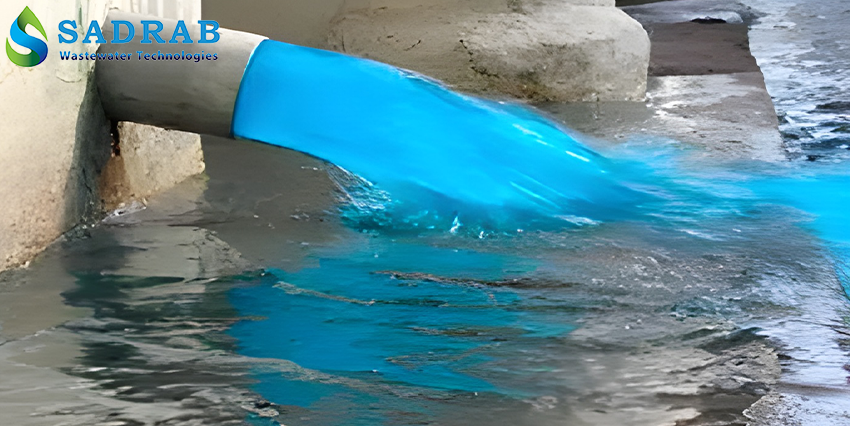

Petrochemical Industry Wastewater Treatment Plant Design

Features of Petrochemical Industry Wastewater Treatment Plant Design:

- Precise customization of packages for specific petrochemical wastewater

- Effective removal capability of toxic and hydrocarbon pollutants

- Modular and upgradeable design to meet changing industrial needs

- Minimal footprint with maximum treatment efficiency

- Easy transport and rapid installation in industrial environments

- Full compliance with the latest environmental standards

- Equipped with intelligent control systems and advanced automation

- Significant reduction in operation and maintenance costs

Specialized support and consulting services

Customized solutions for clients

Quality and performance assurance of products

Expertise in wastewater treatment technologies

Additional Information

Petrochemical Industry Wastewater Treatment: Comprehensive and Professional Solutions for Complex Challenges

Petrochemical industry wastewater treatment is one of the most important and complex processes in industrial wastewater management. Due to the unique characteristics of this industry’s wastewater, advanced and specialized solutions are required. The wastewater from the petrochemical industry contains diverse chemical compounds, resistant pollutants, and large production volumes, creating numerous environmental and technical challenges. In this article, we comprehensively review various aspects of petrochemical wastewater treatment, analyze the nature and types of this industry’s effluents, explain the technical aspects of treatment processes, and evaluate solutions such as wastewater treatment packages, industrial wastewater treatment equipment, and industrial treatment plant design services provided by the Sadrab Wastewater Treatment Company.

Nature and Types of Wastewater in the Petrochemical Industry

Due to the complex processes involved in chemical production, oil refining, and hydrocarbon processing, petrochemical industry wastewater has unique characteristics that must be understood for effective wastewater treatment. The types of wastewater in this industry include:

Organic Wastewater:

Contains hydrocarbon compounds (such as benzene, toluene, and xylene), phenols, and oils generated from refining and chemical production processes. This wastewater typically has high COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) levels.

Inorganic Wastewater:

Includes salts, sulfates, and heavy metals (such as chromium, nickel, and lead) generated from processing units and equipment washing.Oil-Contaminated Wastewater:

Resulting from leaks of oil, grease, and heavy hydrocarbons during refining processes, requiring specialized separation methods.Acidic or Alkaline Wastewater:

With variable pH, originating from chemical processes like acid production or use of alkalis.Wastewater Containing Toxic Substances:

Includes cyanides, ammonia, and other hazardous materials that require special management due to their high toxicity in petrochemical wastewater treatment.This diversity in petrochemical wastewater necessitates multi-stage and combined approaches that can be designed and implemented by specialized wastewater treatment companies like Sadrab.

Petrochemical Wastewater Treatment: Importance and Challenges

Treating petrochemical wastewater is one of the most challenging industrial wastewater treatment processes due to the presence of resistant and toxic pollutants. These effluents can contaminate surface and groundwater and threaten ecosystems. Without proper petrochemical wastewater treatment, petrochemical industries face environmental fines and legal restrictions.

Sadrab, as a leading wastewater treatment company, manages petrochemical wastewater treatment challenges by providing solutions such as industrial wastewater treatment equipment and wastewater treatment packages. These solutions enable the removal of complex pollutants and water recycling, which are beneficial both environmentally and economically.

Wastewater Treatment Package: A Flexible Solution for Petrochemical Industries

Wastewater treatment packages are an efficient option for treating petrochemical wastewater, designed as prefabricated units suitable for smaller or temporary facilities. These packages can perform multi-stage processes within an integrated system and can be customized specifically for managing petrochemical industry wastewater.

Sadrab, by producing advanced wastewater treatment packages, enables the removal of hydrocarbons, oily substances, and heavy metals. Using industrial wastewater treatment equipment in these packages increases the efficiency of petrochemical wastewater treatment and reduces installation and startup costs.

Industrial Treatment Plant Design: Sadrab’s Expertise in Petrochemicals

Designing industrial treatment plants for petrochemical wastewater requires deep technical knowledge and experience in managing complex effluents. These plants are designed for large petrochemical units that generate high volumes of wastewater. Sadrab, as a leading wastewater treatment company, has a unique capability in designing industrial treatment plants tailored to the specific characteristics of this industry.

These treatment plants include multi-stage systems composed of advanced industrial wastewater treatment equipment and chemical and biological processes. Focusing on efficiency and sustainability, Sadrab offers comprehensive solutions for petrochemical wastewater treatment.

Technical Aspects of Petrochemical Wastewater Treatment Processes

Due to the complexity of pollutants, petrochemical wastewater treatment requires advanced technical processes. Below are the key stages and technical aspects of these processes:

Pre-Treatment:

Objective: Removal of suspended solids, oil, and grease from petrochemical wastewater.

Methods: Dissolved Air Flotation (DAF) and gravity separation.

Equipment: Industrial wastewater treatment units equipped with DAF systems by Sadrab.

Technical Aspect: Adjustment of air pressure and flow rate for effective oil separation.

Chemical Treatment (Coagulation and Flocculation):

Objective: Removal of hydrocarbons and heavy metals from petrochemical wastewater.

Methods: Use of coagulants (such as ferric sulfate) and flocculants (polymers).

Technical Aspect: Precise pH control (usually between 6-8) and chemical dosing to optimize floc formation. Sadrab implements this process with high accuracy in its wastewater treatment packages.

Biological Treatment:

Objective: Reduction of COD and BOD in petrochemical wastewater.

Methods: Activated sludge process or MBBR (Moving Bed Biofilm Reactor).

Technical Aspect: Adequate oxygen supply (DO between 2-4 mg/L) and hydraulic retention time (HRT) of 12-24 hours. This method is effective for organic wastewater.

Advanced Treatment:

Objective: Removal of toxic substances and color from petrochemical wastewater.

Methods: Advanced Oxidation Processes (AOP) using ozone or hydrogen peroxide, and membrane filtration (Reverse Osmosis).

Technical Aspect: Operating pressure of 10-50 bar in RO systems and dosing control of oxidants for maximum efficiency.

Sludge Management:

Objective: Disposal or recovery of sludge generated during petrochemical wastewater treatment.

Methods: Dewatering using filter presses or centrifuges.

Technical Aspect: Sadrab designs dewatering systems that reduce sludge volume and optimize disposal.

Conclusion:

Sadrab, Your Consultant for Finding the Optimal Methods in Petrochemical Wastewater Treatment Processes

Treating petrochemical wastewater and managing petrochemical industry effluents are vital needs of this industry. By utilizing a Wastewater Treatment Package, industrial wastewater treatment equipment, and industrial treatment plant design services, comprehensive solutions can be achieved. Sadrab, as a leading wastewater treatment company, offers advanced technologies and customized services, serving as your consultant to find the most efficient methods in petrochemical wastewater treatment processes.

For free consultation and professional solutions in petrochemical wastewater treatment, contact Sadrab at:

09119191911

We are ready to provide you with the best services.

FAQ

Yes, these packages utilize chemical, physical, and biological processes to remove complex compounds such as phenol, ammonia, cyanide, and petroleum compounds.

The petrochemical package is designed for wastewater with specific chemical compositions, high COD, and toxic pollutants, while the industrial package may be suitable for simpler wastewater.

The installation time usually ranges from 2 to 4 weeks, depending on the package capacity, installation site, and project conditions.

Yes, companies like Sadrab fully design and manufacture the package based on the type and analysis of your wastewater.

Maintenance costs vary depending on the system type, consumables, and wastewater volume, but Sadrab’s packages are designed to minimize energy consumption and chemical use.