Design and implementation of wastewater treatment plants for manufacturing industries

Features of designing and implementing wastewater treatment plants for manufacturing industries:

- Customized design for each industry

- Utilization of advanced technologies (MBR, MBBR, RO)

- Full compliance with Iranian and international environmental standards

- Comprehensive sludge and waste management

- Smart monitoring and control with SCADA systems

- Continuous technical support and post-implementation services

- Energy consumption reduction and optimization of operating costs

- Focus on environmental sustainability and circular economy

Specialized support and consulting services

Customized solutions for clients

Ensuring Product Quality and Performance

Expertise in Wastewater Treatment Technologies

Additional information

Design and implementation of wastewater treatment plants for manufacturing industries by SadraAb

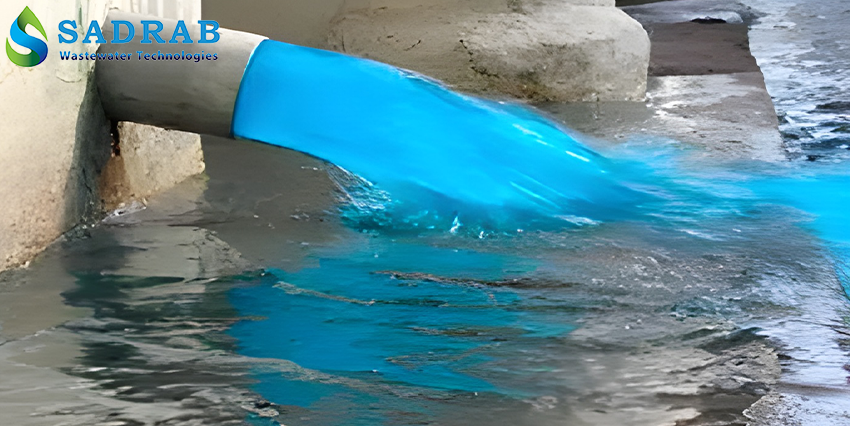

Wastewater management in manufacturing industries is one of the key challenges for environmental protection and compliance with legal standards. Palayesh SadraAb Caspian Company, with over a decade of experience in the water and wastewater treatment industry, offers advanced and sustainable solutions for the design and implementation of wastewater treatment plants for manufacturing industries. Relying on technical expertise, modern technologies, and a strong commitment to the environment, we help industries manage their wastewater efficiently and responsibly.

On this page, we explore the process of designing and implementing wastewater treatment plants by SadraAb, the technologies used, and the benefits of partnering with us.

You may find this interesting: Industrial RO system

What Is an Industrial Wastewater Treatment Plant?

An industrial wastewater treatment plant is a system that treats wastewater generated by industries—such as chemical, pharmaceutical, food, and manufacturing sectors—to remove pollutants like organic matter, heavy metals, and microorganisms. This process not only helps protect the environment but also enables the reuse or safe discharge of treated water. SadraAb designs customized systems to meet the specific needs of each industry.

Steps of Designing and Implementing a Wastewater Treatment Plant by SadraAb

The design and implementation process of a wastewater treatment plant by SadraAb includes the following carefully executed steps:

1.Planning and Feasibility Studies

- Wastewater Analysis: Examination of industrial wastewater characteristics, including pH, COD (Chemical Oxygen Demand), BOD (Biological Oxygen Demand), TSS (Total Suspended Solids), and heavy metals.

- Site Evaluation: Assessment of available space, soil conditions, and proximity to water sources or sensitive ecosystems.

Regulatory Compliance: Ensuring alignment with the standards of the Iranian Department of Environment (DOE) and other international regulations.

- Economic Feasibility: Estimating capital, operational, and life cycle costs (including maintenance and sludge disposal).

2.Technology Selection

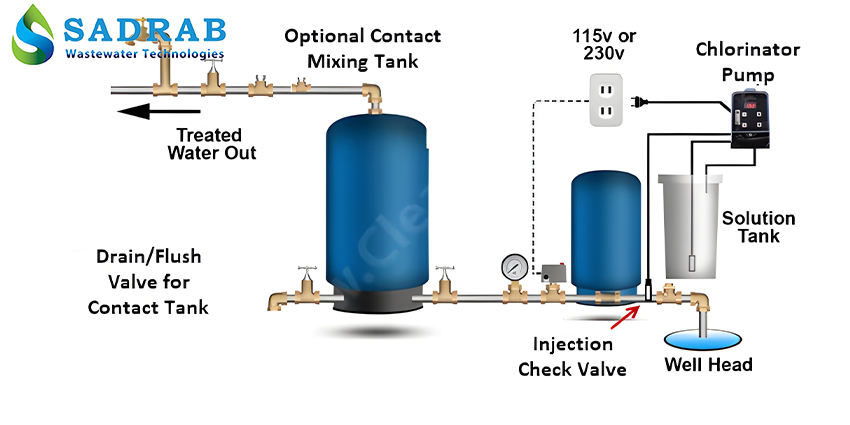

SadraAb selects appropriate technologies based on the type of wastewater and industry requirements. Common technologies include:

Preliminary treatment: Screening, grit removal, and flow equalization.

Primary treatment: Sedimentation or flotation to remove suspended solids.

Secondary treatment: Biological processes such as activated sludge, MBBR (Moving Bed Biofilm Reactor), or MBR (Membrane Bioreactor).

Tertiary treatment: Advanced processes like filtration, adsorption, or chemical precipitation to remove specific contaminants.

Sludge management: Dewatering, stabilization, and disposal or reuse of sludge.

3. Detailed Design

Process design: Layout and flow diagrams of the treatment plant with precise calculations of retention time and hydraulic loading rate.

Mechanical and electrical design: Selection of high-quality pumps, blowers, and control systems.

Civil design: Construction of tanks, channels, and durable structures in accordance with building codes.

Instrumentation: Implementation of SCADA systems for automated monitoring and control.

4. Procurement and Construction

Equipment supply: Use of materials and equipment that meet international standards.

Construction and installation: Project execution under the supervision of SadraAb’s experienced engineers with quality control at every stage.

5. Commissioning and Initial Operation

Testing and commissioning: Performance testing of each unit to ensure compliance with design specifications.

Training: Comprehensive training for operators on system operation and maintenance.

Documentation: Delivery of manuals and maintenance schedules.

6. Operation and Maintenance

Continuous monitoring: Monitoring the performance of the treatment plant to ensure effluent standards are met.

Routine maintenance: Scheduled repairs and part replacements to prevent breakdowns.

Upgrades: Adoption of new technologies to enhance system efficiency.

Technologies Used by SadraAb

SadraAb employs advanced and proven technologies for industrial wastewater treatment. The table below compares some of these technologies:

| Technology | Application | Advantages | Disadvantages |

|---|---|---|---|

| Activated Sludge | Organic matter reduction | High efficiency, moderate cost | Requires energy for aeration |

| MBBR | Biological treatment | Easy maintenance, high capacity | Higher initial cost |

| MBR | Advanced treatment | High effluent quality, enables water reuse | High operational cost |

| Reverse Osmosis | Salt and specific pollutant removal | High water quality | Requires pre-treatment, high cost |

Benefits of Partnering with SadraAb

Experience and expertise: SadraAb’s team offers high-performance solutions backed by years of experience in industrial projects.

Customized solutions: Each project is designed based on the specific needs of the industry.

Sustainability: Use of energy-efficient and eco-friendly methods to reduce environmental impact.

Comprehensive support: After-sales service, training, and regular maintenance ensure optimal system performance.

Standards compliance: Full adherence to local and international environmental regulations.

Applications in Manufacturing Industries

SadraAb’s wastewater treatment plants are suitable for various manufacturing sectors, including:

Chemical industry: Removal of organic compounds and heavy metals.

Pharmaceutical industry: Treatment of wastewater containing pharmaceutical residues.

Food industry: Reduction of BOD and COD to meet discharge standards.

Textile industry: Removal of dyes and chemical substances.

Metal industry: Management of wastewater containing heavy metals.

Why Choose SadraAb?

Commitment to quality: Use of globally standardized equipment and strict supervision at all project stages.

Innovation: Adoption of cutting-edge technologies to enhance efficiency and reduce costs.

Customer orientation: Free consultation and continuous support to ensure customer satisfaction.

Responsibility: Dedication to environmental protection and contribution to sustainable development.

Conclusion

Palayesh SadraAb Caspian Company, through its professional services in the design and implementation of wastewater treatment plants, helps manufacturing industries responsibly manage their wastewater while protecting the environment and complying with legal standards.

By choosing SadraAb, you gain a reliable partner that prioritizes quality, innovation, and sustainability.

Start your project today—contact us now!

FAQ

SadraAb’s engineering team conducts precise wastewater analysis, evaluates site conditions, and reviews your industry’s specific needs to select and design the most suitable treatment technology—such as MBBR, MBR, activated sludge, or reverse osmosis.

Yes. SadraAb offers comprehensive support services, including operator training, provision of technical documentation, periodic maintenance, and system upgrades to ensure continuous and optimal performance of the treatment plant.

Yes, with technologies like MBR and reverse osmosis, the quality of treated water becomes high enough to be reused in industrial applications such as washing, cooling towers, or even certain production processes.

The final cost depends on factors such as wastewater volume, type of contaminants, selected technology, and site conditions. After an initial assessment and feasibility study, SadraAb provides a detailed estimate of capital, operational, and maintenance costs.