Cooling Tower Drift Eliminator

Features of Cooling Tower Drift Eliminator:

- Reduces water loss by up to 99%

- Durable and high-quality construction

- Two design options

- Easy and quick installation

- Lowers maintenance costs

- Increases system efficiency

- Compliant with international standards

- Environmentally friendly

Support and Expert Consultation Services

Customized solutions for clients

Guaranteed product quality and performance

Expertise in wastewater treatment technologies

Additional Information

Sadrab Cooling Tower Drift Eliminator: An Effective Solution for Optimizing Cooling Tower Performance

Cooling towers are vital equipment in various industries for dissipating excess heat. However, water loss through fine droplets (drift) is a major challenge that can increase costs and harm the environment. Sadrab Caspian Water Treatment Company — with over a decade of experience in water treatment and industrial equipment — offers cooling tower drift eliminators as an effective solution to optimize cooling tower performance. This page reviews the features, benefits, and applications of Sadrab’s drift eliminators.

What is a Cooling Tower Drift Eliminator?

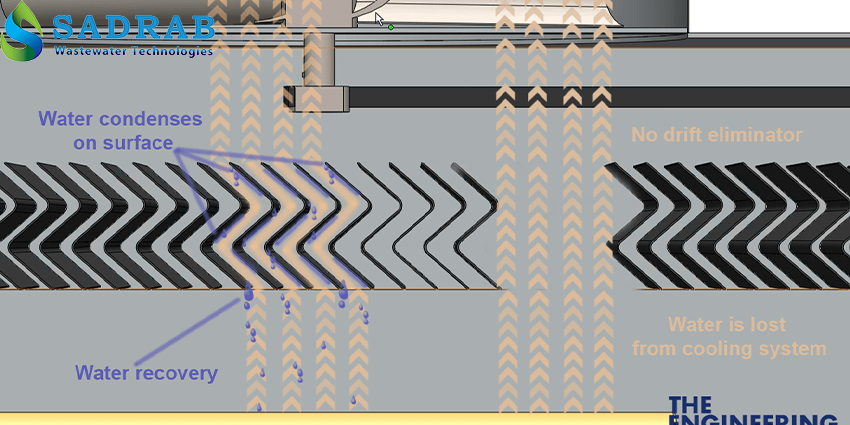

A cooling tower drift eliminator is a component installed at the top of the cooling tower to prevent water droplets from escaping with the outgoing air stream. These droplets, which contain salts and chemicals, are called drift. The drift eliminator traps water droplets by suddenly changing the airflow path, returning them back inside the tower while allowing air to pass through.

You might also be interested in: Home Water Purification System

How It Works

Airflow Redirection: Drift eliminators use complex structures such as baffles or blades to redirect the airflow inside the cooling tower.

Droplet Deceleration: The redirected path reduces the velocity of water droplets, causing them to fall back into the tower.

Minimized Water Loss: By reducing drift, the need for make-up water is significantly decreased.

Importance of Drift Eliminators in Cooling Towers

Water Conservation: Reduces water loss by up to 99%, which is especially critical in water-scarce regions.

Environmental Protection: Prevents the release of chemicals and dissolved solids into the surrounding environment.

Improved Efficiency: Lower drift enhances the thermal performance of the tower and reduces operational costs.

Environmental Safety: Helps avoid icing on nearby roads and equipment in cold climates caused by drifting water droplets.

Types of sadrab Drift Eliminators

sadrab offers a variety of drift eliminator designs suitable for different types of cooling towers:

1. Cellular Drift Eliminator

Honeycomb structure with a high cross-sectional area

Highly effective at capturing water droplets

Ideal for cooling towers with high volume and strong airflow

2. Blade Drift Eliminator

Made of durable blade-like elements

Suitable for installations with limited space

High durability and low maintenance cost

Features of sadrab Drift Eliminators

High-Quality Materials: Made from corrosion-resistant polymers like PVC and PP, resistant to rust and UV rays

High Efficiency: Reduces drift loss to less than 0.002% of the circulating water flow

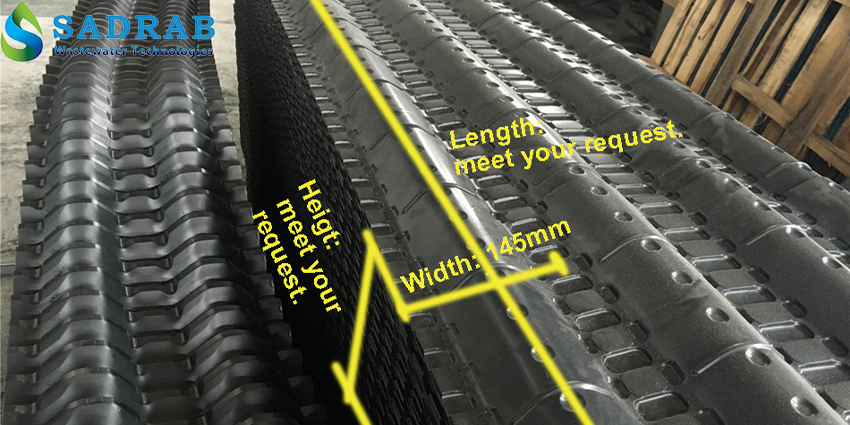

Custom Design: Tailored production based on the specific requirements of each cooling tower

Easy Installation: Modular and lightweight design enables quick and safe setup

Long Service Life: Resistant to harsh environmental and industrial conditions

Applications of sadrab Drift Eliminators

sadrab drift eliminators are used across a wide range of industries:

Oil, Gas, and Petrochemical Industries: Significantly reduce water loss

Power Plants: Improve cooling efficiency and lower operational costs

Manufacturing Facilities: Protect nearby equipment from water droplet dispersion

Commercial Buildings: Prevent issues in HVAC systems caused by water droplets

Advantages of Using sadrab Drift Eliminators

Reduced Water Consumption: Significant savings on make-up water and overall operational costs

Environmental Protection: Prevents the release of chemical-laden droplets into the surrounding environment

Extended Equipment Lifespan: Minimizes corrosion and damage to fans and other cooling tower components

Standards Compliance: Designed in accordance with environmental regulations and international standards

Lower Maintenance Costs: Durable materials and optimized design reduce the need for frequent repairs

Installation & Maintenance

Installation Location: Drift eliminators are typically installed in the upper section of the cooling tower, near the extractor fans

Maintenance:

Periodic Cleaning to prevent clogging from deposits or algae buildup

Regular Inspections to ensure structural integrity and optimal performance

Replacement: If worn out or underperforming, sadrab provides fast replacement services

Key Factors for Choosing the Right Drift Eliminator

| Factor | Description |

|---|---|

| Type of Cooling Tower | Crossflow or Counterflow |

| Airflow Volume | Towers with high airflow require cellular drift eliminators |

| Water Quality | Water with high mineral content needs more resistant materials |

| Installation Space | Blade-type eliminators are better suited for confined spaces |

| Maintenance Cost | Select durable materials to reduce long-term expenses |

The sadrab team will assess your cooling tower conditions and recommend the most suitable drift eliminator.

Contact us today for a free consultation!

sadrab Drift Eliminator Price

The price of a drift eliminator depends on the following factors:

Type of Eliminator: Cellular models are generally more expensive than blade-type.

Size & Capacity: Larger units come at a higher cost.

Material: High-quality PVC and polypropylene (PP) have different price points.

Installation Services: Professional installation may incur additional charges.

For an accurate quote, contact the sadrab sales team and benefit from special offers!

About sadrab Caspian Water Treatment Co.

sadrab is one of the pioneers in Iran’s water treatment and industrial equipment sector, relying on technical expertise and specialized teams in environmental engineering, mechanical, and chemical fields. With successful project implementations across various industries, we are committed to delivering sustainable and high-quality solutions.

Vision: Leading provider of efficient, eco-friendly industrial equipment

Core Values: Quality, innovation, and customer satisfaction

Services: Consultation, design, manufacturing, installation, and technical support

Get in touch with us today to start your collaboration with sadrab!

Conclusion

The sadrab cooling tower drift eliminator is an effective solution for optimizing cooling tower performance. These components significantly reduce water loss, protect the environment, and enhance system efficiency—offering substantial added value to industrial operations. With high-quality products and professional services, sadrab is your reliable partner for cooling system needs.

Contact our team today for more information or to place an order, and take advantage of our free consultation services.

FAQ

A drift eliminator is a component installed at the top of a cooling tower. Its main function is to prevent water droplets from escaping with the outgoing air stream. By capturing and redirecting these droplets back into the system, it reduces water loss and helps optimize the cooling tower’s performance.

A drift eliminator reduces water loss by up to 99%, protects the environment, increases the thermal efficiency of the tower, and lowers operational costs.

sadrab offers two types of drift eliminators: cellular (honeycomb), ideal for towers with high volume and strong airflow, and blade type, suitable for limited spaces with high durability.

Maintenance includes regular cleaning to prevent clogging caused by deposits, periodic inspection of the structure’s condition, and timely replacement of the part if necessary.

The price varies based on the type of drift eliminator, dimensions, construction materials, and installation services. For an accurate quote, it is best to contact the sadrab sales team.