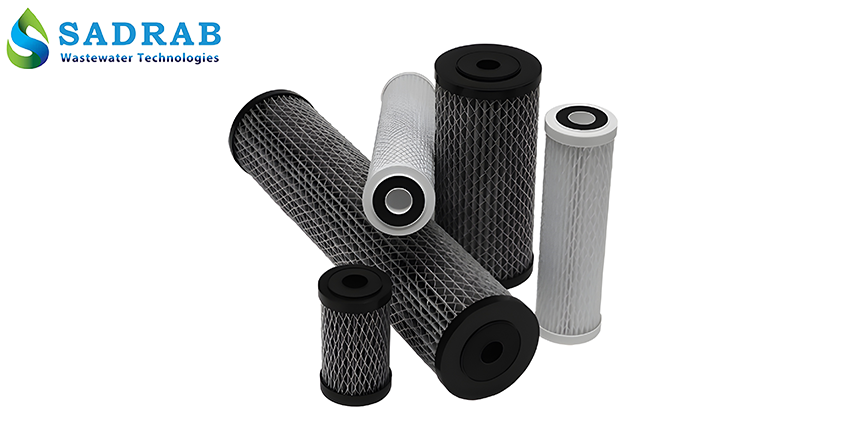

Activated Carbon Filter

Features of the Activated Carbon Filter:

- Focus on the quality of activated carbon and its types

- Review of modern technologies used in filters

- Emphasis on economic and environmental benefits

- Step-by-step guide to the operation of the Sadrab carbon filter

- Key factors in selecting the right carbon filter

- Clarification of the product pricing structure

- Technical support and specialized after-sales services

- Provision of maintenance plans and technical support

Specialized support and consulting services

Customized solutions tailored to customer needs

Guaranteed product quality and performance

Expertise in wastewater treatment technologies

Additional Information

Sadrab Industrial Carbon Filter: A Solution for Removing Chemical Contaminants and Improving Water Quality

Water quality in various industries and facilities directly affects process performance and equipment health. The industrial carbon filter is one of the most effective methods for removing chemical pollutants, odors, and unpleasant tastes from water. Sadrab Kaspin Purification Company — with over a decade of experience in the water and wastewater treatment industry — offers high-performance, custom-designed industrial carbon filters. These filters are ideal for industrial, agricultural, and municipal applications. On this page, we review the features, technologies, benefits, and how to select the appropriate Sadrab industrial carbon filter.

What is an Industrial Carbon Filter?

An industrial carbon filter is a device that uses activated carbon to adsorb chemical contaminants such as chlorine, organic substances, volatile compounds, and unpleasant odors from water. These filters are typically used as part of pre-treatment systems alongside sand filters or independently. Sadrab carbon filters are designed for diverse industrial needs with capacities ranging from a few cubic meters up to hundreds of cubic meters per hour.

Features of Sadrab Industrial Carbon Filters

Sadrab offers industrial carbon filters with the following features:

High-quality activated carbon: Use of granular or powdered activated carbon with a high adsorption surface area.

Varied capacity: Suitable for water treatment with flow rates from 5 to 500 cubic meters per hour.

Durable design: Carbon steel body coated with epoxy or stainless steel for corrosion resistance.

Advanced automation: Equipped with automatic or manual valves for backwash.

Effective contaminant removal: High-efficiency removal of chlorine, organic compounds, and unpleasant odors.

After-sales services: Technical support, valid warranty, and periodic maintenance services.

For ordering Sadrab industrial carbon filters, contact us!

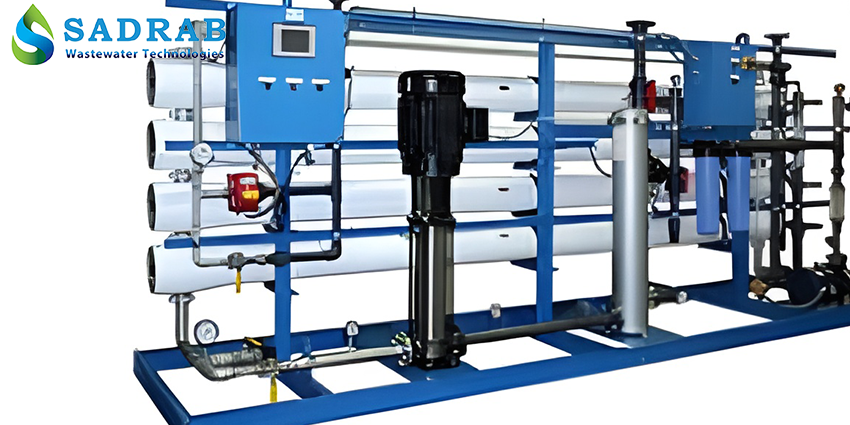

Technologies Used

Sadrab carbon filters utilize the following technologies:

Granular Activated Carbon (GAC): Adsorption of chemical contaminants and organic materials with a high surface contact area.

Backwash: Automatic or manual system for cleaning the carbon bed and extending filter lifespan.

Advanced Hydraulic Design: Uniform water distribution across the carbon bed to prevent channeling.

Pressure Control: Equipped with pressure gauges and control systems to maintain optimal performance.

Durable Materials: Corrosion-resistant coatings and long-lasting carbon beds.

These technologies ensure stable performance of the carbon filter under various industrial conditions.

Benefits of Sadrab Industrial Carbon Filter

Removal of Chemical Contaminants: Efficient elimination of chlorine, organic substances, and volatile compounds.

Improved Taste and Odor: Produces high-quality water suitable for industrial and drinking purposes.

Economic Savings: Low maintenance costs and long lifespan of the carbon bed.

Environmental Sustainability: Reduced use of chemicals in the treatment process.

Equipment Protection: Prevents corrosion and damage to systems such as RO membranes.

Professional Support: Consultation, installation, and specialized repair services provided by the Sadrab team.

How Sadrab Industrial Carbon Filter Works

The Sadrab carbon filter operates through the following steps:

Raw Water Inflow: Water containing chemical contaminants enters the filter.

Contaminant Adsorption: Activated carbon adsorbs contaminants, chlorine, and organic materials.

Treated Water Output: Water with improved taste and odor exits the filter.

Backwash: At regular intervals, water or air flows in reverse through the filter to clean the carbon bed.

Return to Normal Operation: After washing, the filter is ready for reuse.

This process ensures the treated water is suitable for industrial applications, pre-treatment, or drinking use.

Factors for Selecting an Industrial Carbon Filter

When choosing the right carbon filter, consider the following factors:

| Factor | Description |

|---|---|

| Incoming Water Quality | Water with high chlorine or organic content requires activated carbon with a high adsorption capacity. |

| Water Flow Rate | From 5 to 500 cubic meters per hour, depending on project needs. |

| Type of Activated Carbon | Granular (GAC) or powdered, depending on the types of contaminants. |

| Maintenance Cost | Includes periodic replacement of activated carbon and backwashing. |

| Installation Space | Compact design for industrial environments with limited space. |

The Sadrab team analyzes your incoming water and project requirements to recommend the best carbon filter. Contact us for a free consultation!

Price of Sadrab Industrial Carbon Filter

The price of carbon filters depends on the following factors:

Filter Capacity: Higher flow rate filters cost more.

Body Material: Carbon steel with epoxy coating or stainless steel.

System Type: Manual or automatic (with electric valves).

Activated Carbon Quality: Higher purity carbons have higher prices.

Installation Services: Professional installation and training by the Sadrab team.

For accurate pricing and special offers, contact the Sadrab sales team!

Maintenance Tips

Backwash: Every 1 to 7 days, depending on the level of contaminants in the incoming water.

Activated Carbon Replacement: Every 1 to 2 years, depending on water quality and treatment volume.

Pressure Check: Regular monitoring of pressure gauges to prevent filter clogging.

Sadrab Services: Technical support, supply of activated carbon, and specialized repairs.

About Sadrab Kaspin Purification Company

Relying on technical expertise and specialized teams in environmental engineering, mechanics, and chemistry, Sadrab is one of the leading companies in water and wastewater treatment in Iran. With successful projects across various industries, we are committed to providing sustainable solutions.

Vision: To be a pioneer in delivering water treatment technologies for industries and communities.

Values: Quality, innovation, and customer satisfaction.

Services: Consulting, design, manufacturing, installation, and support.

Contact Sadrab today to collaborate with us!

Conclusion

Sadrab industrial carbon filters provide an efficient solution for removing chemical contaminants and improving water quality in industries, agriculture, and municipal facilities. With advanced technology, durable design, and professional services, Sadrab guarantees the quality of your water and the sustainability of your processes. For selecting the right carbon filter and receiving a free consultation, contact our team 09119191911.

FAQ

An industrial carbon filter is primarily used to remove chlorine, organic substances, volatile compounds, unpleasant odors, and tastes from water. It also helps reduce harmful chemical levels and protects downstream equipment such as RO membranes.

The final price depends on factors such as capacity (water flow rate), body material (steel or stainless steel), system type (manual or automatic), quality of activated carbon, and installation and commissioning services.

Depending on the quality of the incoming water and usage, the activated carbon bed usually needs to be replaced every 1 to 2 years. Additionally, backwashing should be performed regularly (every 1 to 7 days) to prevent filter clogging.