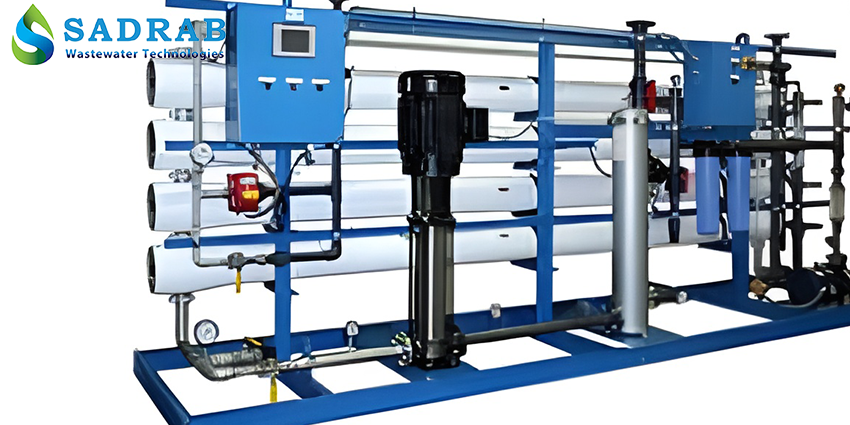

Industrial Water Desalination System

Features of Industrial Water Desalination Systems:

- Custom-designed for your industry's needs

- DOW and Toray membranes removing up to 98% of dissolved solids

- Optimized energy consumption for maximum savings

- Easy maintenance with low operational costs

- Complete removal of contaminants for ultra-pure water

- Various capacities from 10 to thousands of cubic meters

- Environmentally friendly with minimal wastewater

Expertise in advanced wastewater treatment technologies

Guaranteed product quality and performance

Customized solutions tailored to each client

Professional support and expert consultation

Additional Information

Industrial Desalination System: A Smart Solution for Water Treatment in Industry

In today’s world, the shortage of fresh water resources is one of the biggest challenges faced by various industries. Companies and industrial units require high-quality treated water to maintain sustainable operations. In this context, industrial desalination systems have emerged as advanced solutions in water purification with a significant role.

sadrab, as a manufacturer of industrial desalination systems, utilizes technical expertise and modern technologies to deliver reliable solutions for different industrial sectors. In this article, we will explore the applications and types of industrial desalination systems and highlight the unique advantages and features of sadrab‘s products.

Importance of Water Treatment in Industry

Industries such as oil, gas, petrochemicals, food, textiles, agriculture, and power plants require water with specific quality standards for their production processes. Pollution in surface and groundwater resources, increased water hardness, and the presence of salts and harmful chemicals have made the direct use of raw water in industrial processes infeasible.

Under these circumstances, the use of industrial desalination systems becomes essential to eliminate salts, heavy metals, bacteria, viruses, and other contaminants.

Recommended Article: Design and Implementation of Wastewater Treatment Plants for Textile Industries

What Is an Industrial Desalination System?

An Industrial Water Desalination System is a technology designed to treat saline water or water with high levels of dissolved solids. By using processes such as Reverse Osmosis (RO), these systems convert raw water into high-quality water suitable for industrial applications.

Types of Industrial Desalination Systems by Treatment Method

Reverse Osmosis (RO)

Most widely used method

Removes over 98% of dissolved solids

Lower energy consumption compared to thermal methods

Electrodialysis (ED)

Suitable for water with medium TDS levels

Performs well with low-hardness water

Thermal Distillation (MED – MSF)

Designed for very high salinity water (e.g., seawater)

Higher energy consumption

Nanofiltration (NF)

Removes organic compounds and large molecules

Suitable for pre-treatment and specialized processes

Why Should Companies Use Industrial Desalination Systems?

Lower operational costs by reducing scale and corrosion in equipment

Increased efficiency of cooling systems and boilers

Improved quality of final products

Compliance with environmental standards

Reduced dependence on municipal freshwater or limited underground water resources

Advantages of sadrab Industrial Desalination Systems

sadrab, with over 16 years of experience in designing, manufacturing, and implementing industrial water and wastewater treatment projects, is one of the leading companies in this field in Iran. Some of the key features of sadrab’s industrial desalination systems include:

Custom design tailored to the specific needs of each industry

Use of high-quality membranes and components (DOW, Toray, etc.)

Optimized energy consumption and low maintenance costs

Professional technical support and after-sales services

Integration with remote monitoring systems

Applications of Industrial Desalination Systems in Various Industries

Food and Beverage Industry: Supplying high-quality water for hygienic product manufacturing

Petrochemical and Refinery Plants: Treating boiler feed water and cooling towers

Power Plants: Providing pure water for steam generation systems

Pharmaceutical Industry: Delivering ultrapure water for drug formulation

Agriculture and Greenhouses: Providing salt-free, contaminant-free water to boost crop productivity

Important Points in Choosing an Industrial Desalination System

To select a suitable device, the following factors must be considered:

Required capacity (m³/day)

Type and source of feed water (brackish, well water, semi-saline, seawater)

Detailed analysis of raw water

Output water quality standards

Installation space and environmental conditions of the project

The experts at sadrab are ready to design and recommend the best industrial desalination system model based on your project’s technical specifications.

For more information or to order a package, contact the sadrab team and benefit from the experience and expertise of this company.

Sadrab’s Services in Water Treatment

Sadrab is not just a manufacturer of industrial water desalination systems but also a technical consultant and partner throughout all stages of your water treatment project:

On-site project visits and free consultations

3D system design before construction

Complete EPC project execution

Operator staff training

Long-term warranty and support services

Final Words

In conditions where both the quality and quantity of water resources face challenges in many regions of the country, using industrial water desalination systems is not only a technical necessity but also a smart investment for the future of any industrial business. With experience, expertise, and innovation, Sadrab is ready to meet your diverse water treatment needs.

For more information and free consultation, visit www.sadrab.com.

FAQ

To choose the right system, several key factors must be considered: the type of water source (such as well, brackish, or seawater), total dissolved solids (TDS) level, daily consumption capacity, required output water quality, and the installation environment conditions. Reverse osmosis (RO) systems are usually the first choice in most industries, but Sadrab analyzes the raw water and project conditions carefully to design and recommend the best option for you.

The final cost depends on the system capacity, type of equipment (membranes, pumps, controllers, etc.), quality of the incoming water, and the required level of treatment. Reverse osmosis (RO) systems usually have reasonable startup costs and low maintenance expenses. Sadrab, due to optimized design and the use of high-quality components, has minimized maintenance costs and also provides comprehensive technical support services.

Yes. If your feed water has very high salinity (such as seawater), specialized high-pressure RO systems or thermal methods like MED/MSF are used. Sadrab has experience in designing and implementing seawater desalination projects for coastal industries and water-scarce regions and can recommend the most suitable system based on your needs.